Fiberglass FRP Stair Tread Covers Revitalize Old Stairs

Fiberglass FRP Stair Tread Covers easily install over existing metal, wood or concrete stairs to instantly improve safety, usability, visibility, and aesthetics.

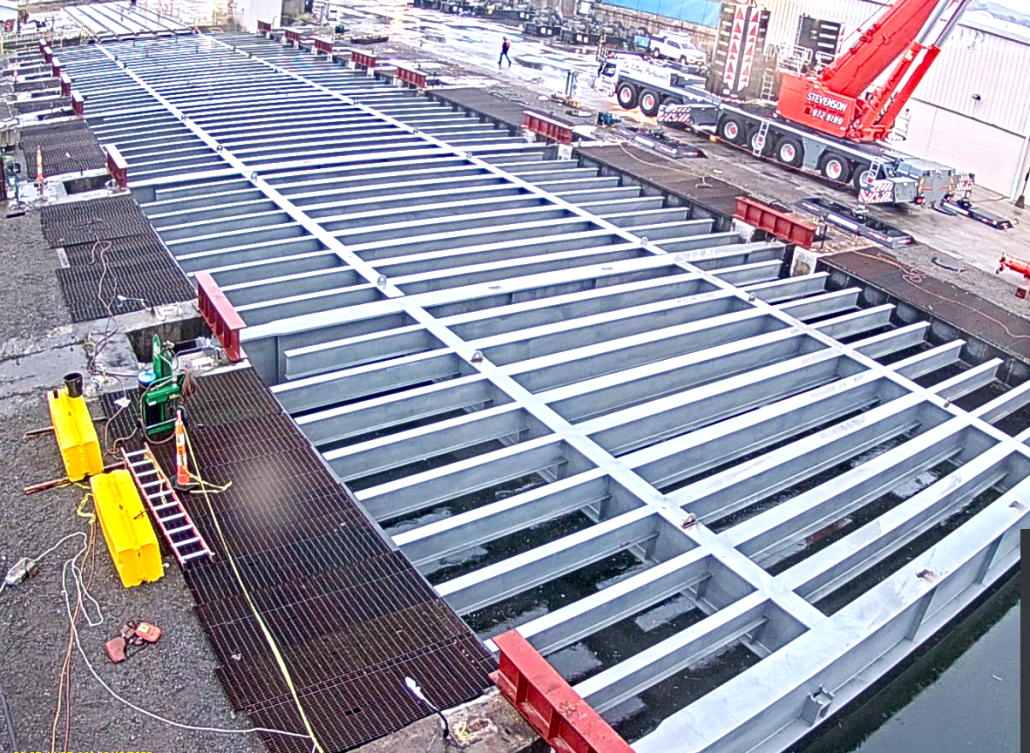

National Grating recently assisted a small business in Ontario to revitalize their old steps with Fiberglass FRP Stair Tread Covers. The outdoor staircase provides access to the Yoga Studio on the second level of the building. The old stairs were rusting and becoming unsightly and hazardous. Fiberglass FRP Stair Tread Covers were easily installed over the existing metal stairs.

Entrances are the first impression for customers approaching your business. The unsightly stairs leading to the Yoga Studio not only provide access to clients, but they are also the first thing people see before they enter the business and the last thing they see when they leave. The rusting, old stairs looked terrible and presented a bad first impression for clients. The Yoga Studio decided it was time for an update! New National Grating FRP Stair Treads cover up old stairs without need for a new rebuild, while providing added safety through bright yellow nosing and a grippy anti slip coating.

New FRP Stair Treads cover up old unsightly stairs without need for a new rebuild, while providing added safety through bright yellow nosing and a grippy anti slip coating.

People use FRP (fiberglass reinforced plastic) stair tread covers for several reasons, including safety, durability, and ease of installation. FRP stair tread covers are known for their non-slip properties, which enhance safety on stairs. They are lightweight, making them easy to install, and fiberglass-reinforced plastic is durable and resistant to corrosion, making it a suitable material for enhancing stair safety.

Fiberglass FRP Stair tread covers from National Grating have been widely installed over metal, wooden, and concrete stairs with ease.

FRP Stair Tread Cover Benefits

The benefits of using FRP (fiberglass reinforced plastic) stair tread covers over traditional materials include:

- Safety: FRP stair tread covers are known for their non-slip properties, which enhance safety on stairs.

- Durability: Fiberglass-reinforced plastic is durable and resistant to corrosion, making it a suitable material for enhancing industrial stair safety.

- Ease of Installation: FRP stair tread covers are lightweight, making them easy to install.

- Versatility: They can be used on various surfaces such as step ladders, concrete, wood, and metal stairwells.

- Cost-Effectiveness: They can cover worn-out or outdated steps, saving money by avoiding the need for expensive rebuilds.

Overall, the use of FRP stair tread covers offers advantages in terms of safety, durability, ease of installation, versatility, and cost-effectiveness compared to traditional materials.

FRP Stair Tread Cover Applications

FRP (fiberglass reinforced plastic) stair tread covers have various applications due to their beneficial properties. Some of the common applications include:

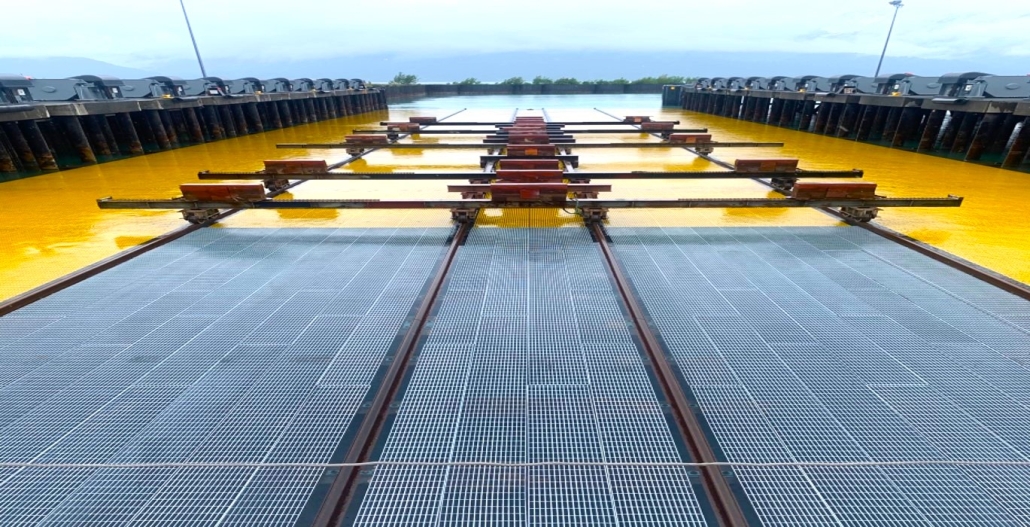

- Interior and Exterior Use: FRP stair tread covers are suitable for both interior and exterior applications, making them versatile for use in different settings.

- Industrial Settings: They are used in industrial settings to enhance safety on stairs, walkways, and platforms, especially in heavy traffic areas where anti-slip surfaces are essential.

- Outdoor Walkways: FRP stair tread covers are ideal for outdoor walkways due to their anti-slip surfaces, providing an important safety feature in areas with heavy foot traffic.

- Various Substrates: They can be used on a variety of substrates such as concrete, wood, stone, metal, and brick stairs, making them suitable for different types of stairwells.

- Safety Enhancement: These covers are designed to reduce accidents caused by slips and falls, making them a practical and affordable solution for protecting steps.

FRP stair tread covers are widely used in industrial, outdoor, and indoor settings to improve safety, protect steps, and provide anti-slip surfaces on various substrates.

How to Install FRP Stair Tread Covers

To install FRP (fiberglass reinforced plastic) stair tread covers over metal stairs, the following general steps can be followed:

- Contact National Grating to speak with an experienced individual to help you make the best decision.

- Measure: Take measurements of the stair treads so the National Grating fabrication team can size your stair tread covers for a perfect fit. Assess how many stair tread covers you require.

- Preparation: Ensure that the metal stairs are clean, dry, and free from any debris or protrusions that could affect the installation.

- Attachment: Use stainless steel or zinc plated saddle clips and domed or flat head bolts suitable in length for the depth of the FRP tread covers. Pre-drill the FRP to the proper hole size for the screws being used.

- Installation: Pre-position the FRP covers in place to ensure the fit, then install screws about 6 inches from the ends of the piece, and additional screws every 2 feet as needed.

Once installed, ensure that the covers are securely and firmly attached and provide a non-slip surface for safe use before opening to the public.

Other Fiberglass FRP Stair Options from National Grating

Fiberglass FRP Stair Treads

National Grating also has full FRP Molded Stair Treads for situations when the existing stair needs to be replaced or for new staircase construction.

Fiberglass stairs are the best solution for outdoor anti-slip stairs. They outlast traditional building materials and are easy to install. Stair treads made of FRP grating are lightweight, easy to fabricate, and highly durable.

Fiberglass stair treads are available as molded FRP treads with yellow nosings and a gritted top surface for all weather grip, for the ultimate in safety. Non-slip stair treads are corrosion resistant and lightweight.

Fiberglass stairs can be fabricated from fiberglass grating, which opens up the options enormously for color, resin, grit, mesh size, and whether molded fiberglass grating or pultruded FRP grating is more suitable.

Fiberglass FRP Railing

Fiberglass Railing Systems are a natural accompaniment to fiberglass stairs for corrosive environments – all components will outlast and outperform steel, stainless steel, wood, or other traditional materials.

FRP railing is non-conductive and in cold environments does not become cold to the touch like metal.

Fiberglass FRP Plate

Fiberglass Plate is a large sheet of FRP that comes in a variety of colors with an anti slip, grippy coating. FRP plate is perfect to cover unsightly landings and platforms with a solid anti slip surface.

FRP Plate comes in thicknesses ranging from 1/8″ to 3/4″ and various resin systems. Plate can be installed on fiberglass grating, metal or concrete, for heavy loads and complete flooring system with all the benefits of fiberglass reinforced panels.

National Grating Customer Service

National Grating prides itself on providing exceptional customer service to all customers, big and small.

Reach out to us today for your next FRP Project!

Sales@NationalGrating.com / 1-844-599-0260