What are people saying about National Grating?

We often receive feedback from our customers regarding our products and customer service. We want to share some of that feedback with you.

At National Grating we take customer service seriously. We realize that our customers are busy, so we are here to answer the phone and help. Simple as that.

National Grating Customer Reviews

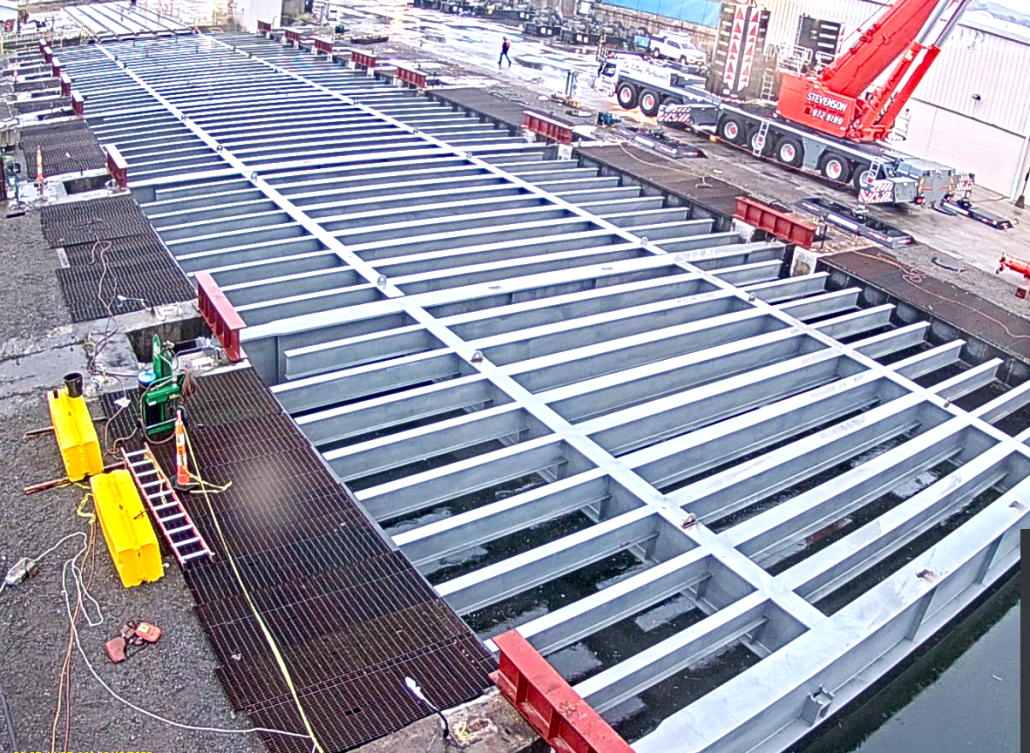

Here is the look of the progress right now from shore.

We are using existing piles and your structural components to stabilize them and tie it all together.

All fasteners are ½” Dia – 316 Stainless Steel, with Nylok Nuts. Lateral bracing is in 6” I beams, stringers are 8” H Beam facia is 8” C-Channel. Cross ties to piles in 12” C – Channel. Cross beams to piles with ¾” – 316 Stainless all thread with 316 Stainless Nylok nuts.It is an incredible look and STRONG structure. I was amazed at how tightly it is holding everything together. A truly remarkable product that is making an amazing finished product.

If you want to come look, or want more information let me know.

First Name: Fred

State/Province: US Virgin Islands

Industry: Construction

National Grating FRP Solution: Molded Mini-Mesh FRP Grating

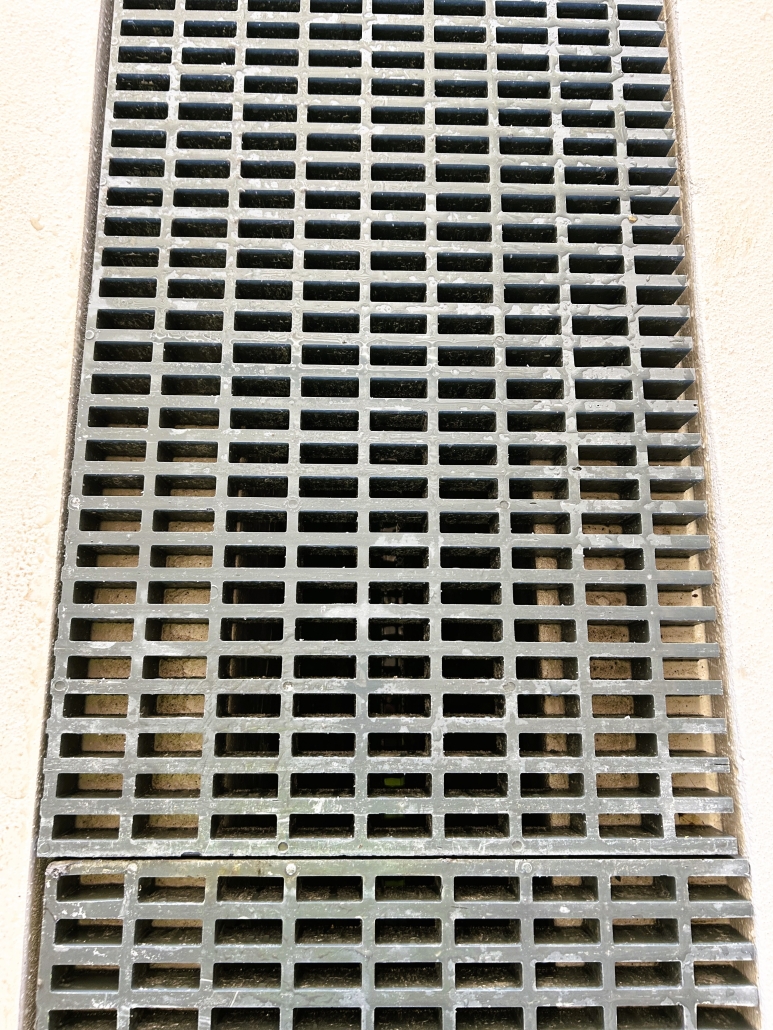

Attached are some photos of the new grating National Grating supplied for the City of Onalaska Fire Bay Floor Repair project. Grating fit perfect and I really appreciated all the assistance from National Grating on the project. Also, fairly sure my wife will put the gift card to good use.

Thanks,

Kevin

First Name: Kevin

State/Province: Wisconsin

Industry: Emergency Services

National Grating FRP Solution: Custom Cut Heavy Duty Molded FRP Grating

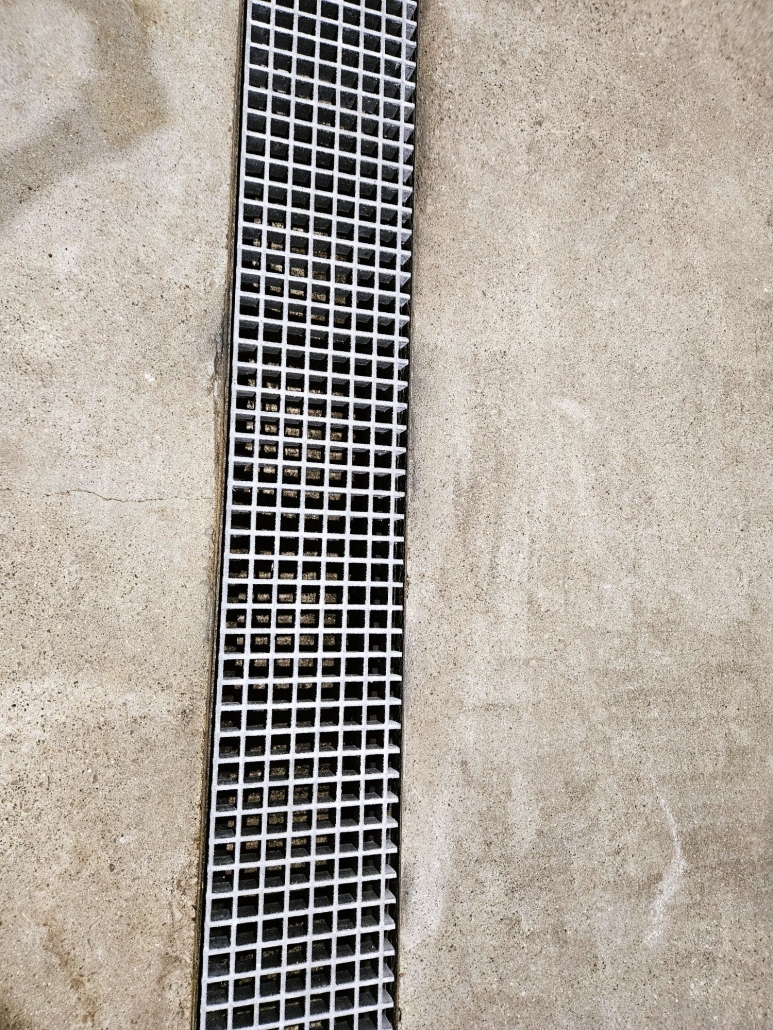

Thanks for the timmies card! Really appreciated! Here are a few pics!

First Name: Tim

State/Province: Ontario

Industry: Winery

National Grating FRP Solution: Custom Cut Molded FRP Grating

You can see on attachment some pictures of our installation with your products. We appreciate it a lot!

Best Regards

First Name: Alexis

State / Province: Quebec

Industry: Aerospace

National Grating FRP Solution: Molded FRP Grating

Hi Dylan

I bought some grating from you a couple months ago.

Just wanted to let you know I did receive your gift card, that was very thoughtful.

My project was delayed due to weather and vacations. But I did cut and install the grating today.

I’m sure it is an unusual application. I was rebuilding the deck that is on top of my house and needed material that could span the 43 inches across the peak without contacting it, there was only a couple of inches for clearance. The original deck design had supports that rested on top of the shingles which caused leakage.

Your fiberglass grating was the only solution I could find .

I’ll send a photo of the finished deck in a few weeks!

First Name: Gerald

State / Province: Wisconsin

Industry: Construction

National Grating FRP Solution: Pultruded FRP Grating

Hi Dylan, received your letter in the mail, very nice touch, its not very often we see any hand written letters these days, let alone a GC.

I have attached a couple pictures of the FRP grating that I installed on my dock gangway. Its looks so much better then the old plywood.

When my neighbours compliment me on it I’ll make sure to pass along your info so they can do there docks as well.

Now I’m off to Tim Horton for my afternoon coffee.

Thank you.

First Name: Jason

State / Province: British Columbia

Industry: Marine

National Grating FRP Solution: FRP Mini Mesh Molded Grating

The decking worked out very well on our project!

The docks are fully assembled and have been installed at the Boat Launch right next to the Yacht Club.

I have attached a couple of photos for you to have a look at, but I encourage you to go take some of your own as well!

If you are in the neighborhood, please feel free to drop in and say hi.

First Name: Nick

State / Province: British Columbia

Industry: Marine

National Grating FRP Solution: FRP Mini Mesh Molded Grating

Thank you for the Tim’s card

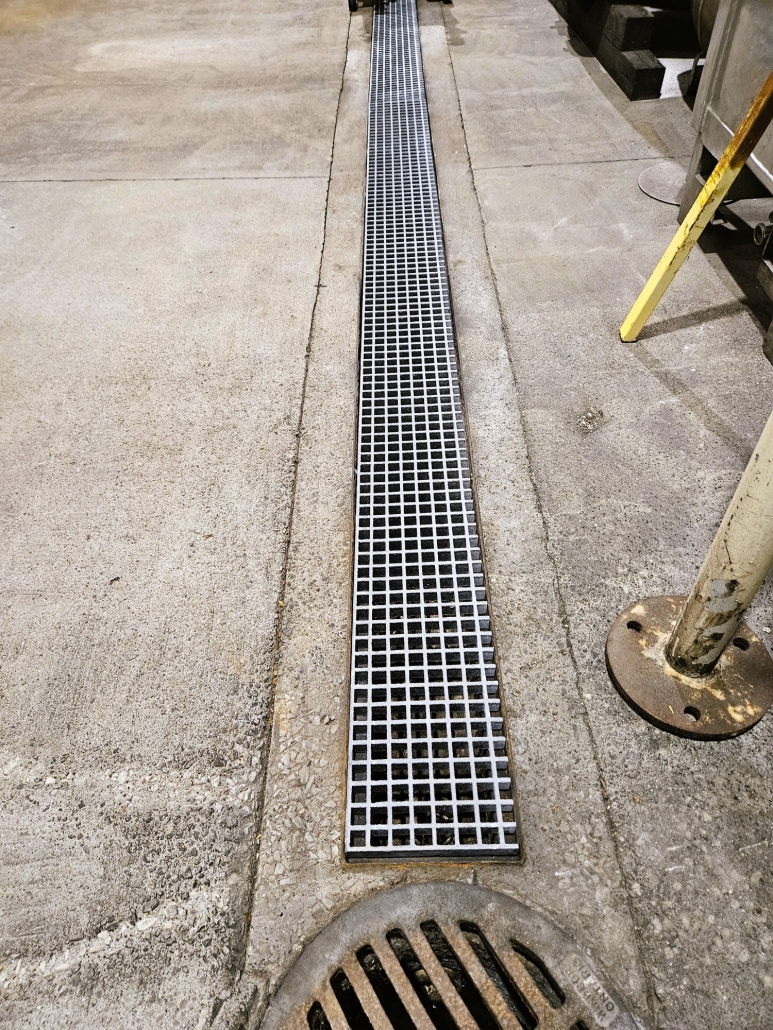

I will certainly buy Tim’s for the team. Here are a couple of pictures. The team members really like the new floor.

Thanks

Paul

First Name: Paul

City: Tillsonburg

State / Province: Ontario

Industry: Automotive

National Grating FRP Solution: Molded FRP Grating

Hi Braden

We just installed a 110 ft dock at a Marina on the Island. Looks sharp.

First Name: Ben

City: Vancouver

State / Province: British Columbia

Industry: Construction

National Grating FRP Solution: Molded FRP Grating

Hello Dylan,

The product worked great and is 10 times better than the steel grates we had in the past. We will not be needing any more but will definitely share with our other locations.

First Name: Denis

City: Toronto

State / Province: Ontario

Industry: Business Services

National Grating FRP Solution: Molded FRP Grating

Hi Dylan,

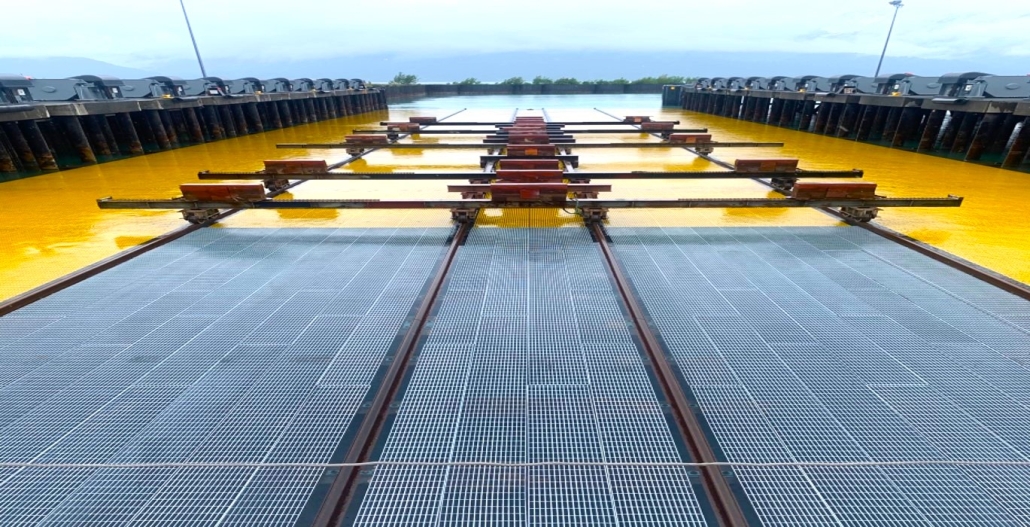

Here is a picture of our dry dock. We still need to put some grating on our landings, but it is looking great!

First Name: Juan

City: Lemont

State / Province: Illinois

Industry: Shipping

National Grating FRP Solution: Pultruded FRP Grating

Hi Dylan, they are definitely much needed traction on these ramps. So far, they’re holding up well against cold, salt and snow.

Derek

First Name: Derek

City: Brant

State / Province: Ontario

Industry: Health

National Grating FRP Solution: FRP Plate

Attached are three photos, the first two are of the steel grates at our London plant.

We replaced them with your dark grey HLC.

Thanks,

First Name: Jim

City: London

State / Province: Ontario

Industry: Food

National Grating FRP Solution: Heavy Duty Fiberglass Grating

Hello,

The grating is working well and you can see already getting worked in with some dirt from the garage floor.

Ian

First Name: Ian

City: London

State / Province: Ontario

Industry: Agriculture

National Grating FRP Solution: Heavy Duty Fiberglass Grating

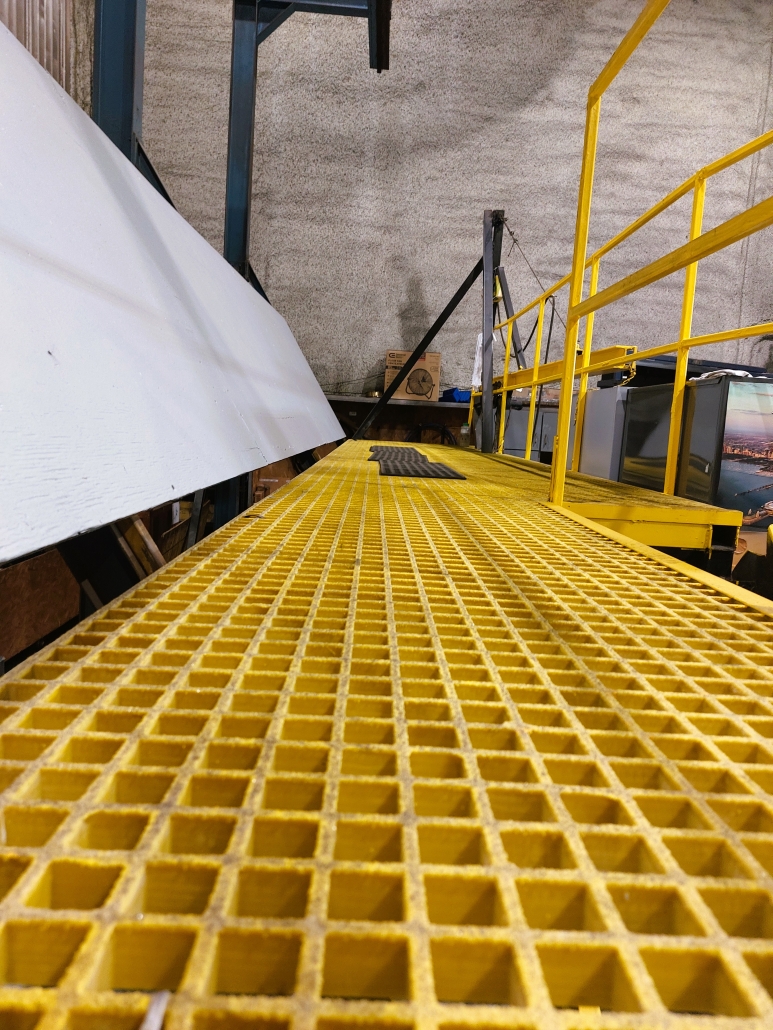

Hi Dylan,

Thanks for the Tims Card and the note.

I attached a few pic’s of the installed grating …..should have done it before it got dirty.

First Name: Shawn

City: Calgary

State / Province: Alberta

Industry: Oil and Gas

National Grating FRP Solution: Molded FRP Grating

Grippy stairs NOW!!! We are quite pleased with these!

( BUT you still need to hold the railing😉)

City: Woodstock

State / Province: Ontario

Industry: Fitness

National Grating FRP Solution: FRP Stair tread Covers

More info: Fiberglass FRP Stair Tread Covers Revitalize Old Stairs

Hi Dylan,

Just wanted to send a note and thank you for the Tims card the crew appreciated it.

I appreciate the customer support by you and Amy.

Thanks Again

First Name: Kevin

City: Calgary

State / Province: Alberta

Industry: Environmental Remediation

National Grating FRP Solution: Molded FRP Grating

Thanks for the email and checking in!

We greatly appreciated the hand-written card and gift card. We send hand-written thank you cards too and to see we’re not the only ones still practicing good ol’ thank-you cards certainly brings a smile to my face! 😊

The grating is working well for our application, with a few adjustments on our end as previously we had a solid platform so levelers on legs would go right through now.

Durability and sustainability is certainly there and so far we’re quite pleased with the product.

Thanks again for reaching out!

I hope you’re having an incredible week!

First Name: Jaclyn

City: Calgary

State / Province: Alberta

Industry: Corporate Services

National Grating FRP Solution: FRP Mini Mesh Molded Grating

Quick thank you for the card and starbucks card. I will make sure to use it and buy the office a drink. Our customers do not allow pictures in their facilities or we would gladly send you pictures. We cut them down into brush handles to use for washing trucks. We need them stiff, chemical resistant, and light weight and this worked perfectly.

First Name: Nathan

City: Salina

State / Province: Kansas

Industry: Corporate Services

National Grating FRP Solution: FRP Tube

Hi Dylan,

Our accounting team here is working on the credit application and setting up an account in our PO software. When this is completed, you should expect a PO for the grating.

Your team was very helpful and prompt with quoting.

Thanks

Ian

First Name: Ian

City: Campbell River

State / Province: British Columbia

Industry: Manufacturing

Bonjour capitaine,

Tel que discuté, voici l’information reçu de Maurice, il me dit que c’est un excellent produit, la capacité de charge est de 300lbs au pieds carré pour le 1 pouce d’épaisseur et de 900lbs au pieds carré pour le 1 1⁄2 pouce d’épaisseur. Vous connaissez mieux ça que moi alors dite moi si le 1 pouce est suffisant ou pas?

Salutations!

Hello Mario, voici une example de grating en fibre de verre. Faite sur de commander avec une grit. https://fiberman.ca/steel-grating-alternative-frp-grating-canada/

MARIO

Translation

Hello Captain,

As discussed, here is the information received from Maurice, he tells me that it is an excellent product, the load capacity is 300lbs per square foot for the 1 inch thick and 900lbs per square foot for the 1 1⁄2 inch thick. You I know this better than I do, so tell me if the 1 inch is enough or not?

Regards!

Hi Mario, here’s an example of fiberglass grating. Made safe to order with a grit. https://fiberman.ca/steel-grating-alternative-frp-grating-canada/

First Name: Mario

City: Cap-aux-Meules

State / Province: Quebec

Industry: Marine

We don’t use a ton of FRP Grating but anytime we do you are the only people we call. This is all due to Chris and his positive attitude. He makes us feel important like we are your only customer and everytime I talk to him he goes above and beyond for us.

City: Savannah

State / Province: Georgia

Industry: Manufacturing

Hi Dylan,

We needed a quote to be able to evaluate the cost of a future project, we are good for now.

Your team handle my request in a professional manner and promptly, I can’t complain.

Thank you,

Jean-François

First Name: Jean-François

City: Gatineau

State / Province: Quebec

Industry: Pulp and Paper

Dylan,

The product is easy to cut and install. We should be complete by end of week with the FRP install. If I have

something else specified or have a need, I will contact you. Thank you for all your help, your team did a

great job.

Chris

First Name: Chris

City: Las Vegas

State / Province: Nevada

Industry: Construction

Dylan,

You and Cody were a pleasure to work with. The communication was great and I appreciate how you quickly fulfilled our order.

We just broke ground on another school project and plan on making another purchase late next year.

Have a nice holiday!

Thanks,

Matt

Dylan,

The grates worked out great for us. We are looking to purchase 76 more along with around 850 of the clips. Would you please work up a new invoice for us?

Please plan on shipping it to the same location. Let me know if you need additional information from me.

Thanks,

Matt

First Name: Matt

City: Chicago

State / Province: Illinois

Industry: Construction

Thank you so much Sarah,

You’ve made the ordering and transaction very easy and affordable for me and as a busy small business person I really appreciate that .

I’m excited to use this product and be able to offer it as an option to my clients .

Cheers

First Name: Joe

City: Cambridge

State / Province: Ontario

Industry: Boating

How long does it usually take to set up an account with your team? Your prices are very reasonable and quick to response, we love that here. Do you mind sending me the spec sheet for this material.

Thank you,

Daniel

First Name: Daniel

City: Huffman

State / Province: Texas

Industry: Construction

No worries. You guys are always my first choice. Thanks for all the hard work you put in, have a great weekend.

Patrick

First Name: Patrick

City: Marietta

State / Province: Georgia

National Grating Fiberglass Reinforced Plastic (FRP) Solutions:

- Molded FRP Grating

- Pultruded FRP Grating

- Mini Mesh FRP Grating

- Heavy Duty / High Load Capacity FRP Grating

- Structural Shapes

- Stair Treads and Covers

- Fiberglass Plate

- Fiberglass Tubing

- Fiberglass Railing

- Threaded Rod and Nuts

- Grating Clips

- Specialty Products

National Grating Customer Service

National Grating prides itself on providing exceptional customer service to all customers, big and small.

Reach out to us today for your next FRP Project!

Sales@NationalGrating.com / 1-844-599-0260