Pultruded FRP Grating: The Ideal Solution for Canadian Marine Dry Docks and Rail Yards

National Grating has been seeing high levels of interest in Pultruded FRP Grating for applications such as Marine Dry Docks across Canada, North America and even as far north as Alaska due to its winter advantages.

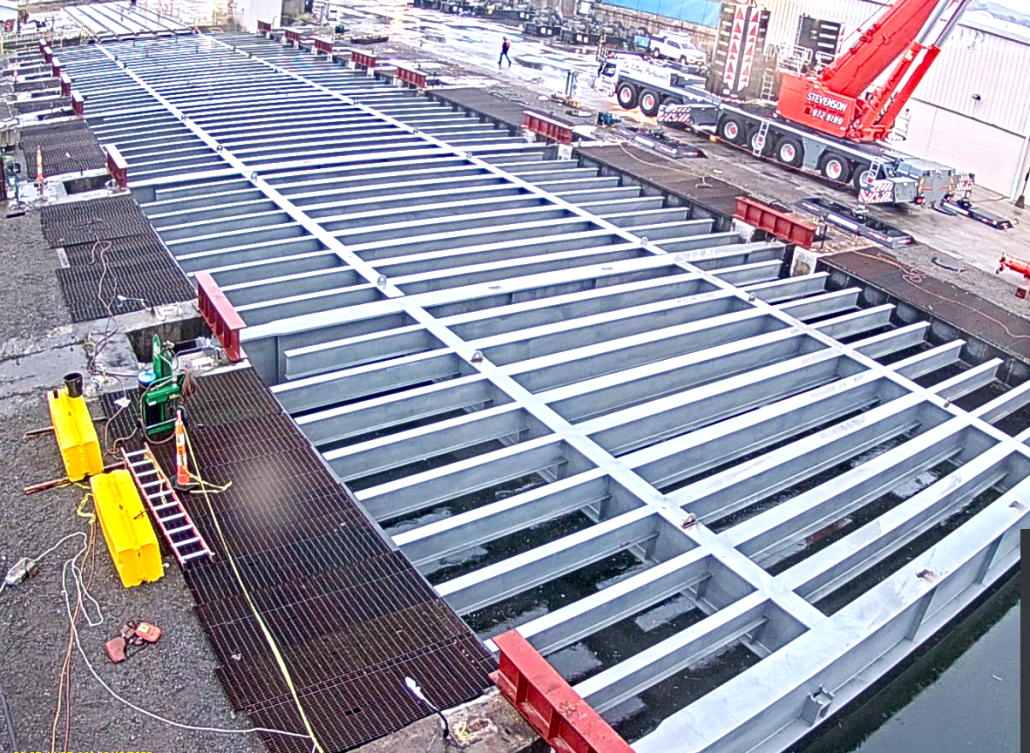

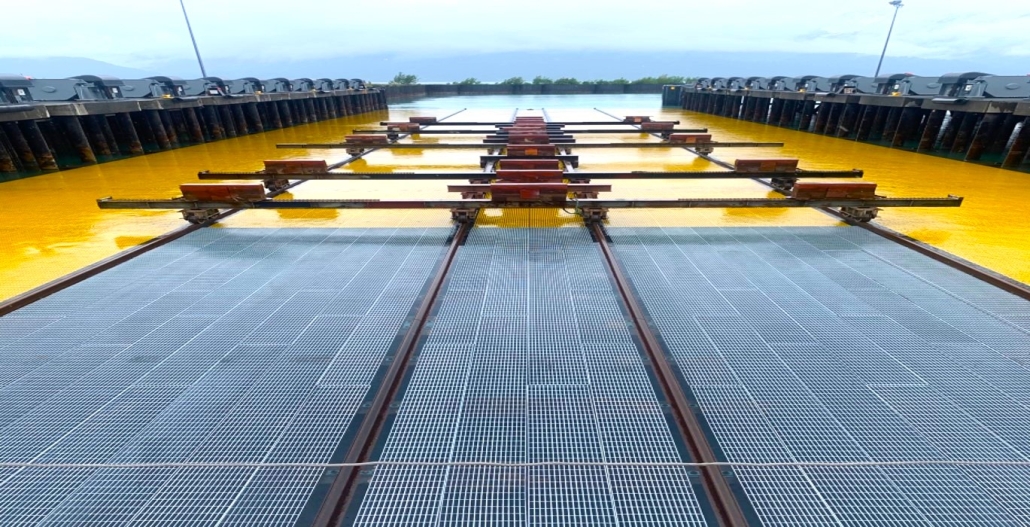

This Marine Towing Drydock operating in the Great Lakes has found the perfect solution for its demanding environment with the implementation of Pultruded T-5000 FRP Grating from National Grating. This innovative grating, engineered from fiberglass-reinforced plastic (FRP), offers a comprehensive set of advantages that address the specific needs of the rail yard, ensuring enhanced performance and durability.

Corrosion Resistance and Longevity

Pultruded FRP Grating is designed to withstand the harshest environments, making it an ideal choice for the Marine Towing Drydock Rail Yard. Its superior corrosion resistance, surpassing traditional materials such as stainless steel, aluminum, and galvanized gratings, ensures longevity and minimizes maintenance requirements.

Heavy-Duty Performance

Engineered to carry higher loads, Pultruded T-5000 Grating delivers exceptional strength and stiffness, making it well-suited for the rigorous demands of the rail yard. Its heavy-duty design provides the necessary support for various operational activities, contributing to a reliable and robust infrastructure.

Safety and Efficiency

The safety surface of Pultruded T-5000 Grating, featuring a coarse epoxy grit, enhances worker safety, even in challenging conditions. This prioritization of safety aligns with the dry docks commitment to maintaining a secure working environment for its personnel.

Low Maintenance and Cost-Effectiveness

The implementation of Pultruded T-5000 Grating offers the Marine Towing Drydock Rail Yard a low-maintenance solution, reducing the need for frequent repairs and upkeep. Furthermore, its cost-effectiveness and long-term performance make it a valuable investment for the rail yard’s operational infrastructure.

Pultruded Grating stands as the optimal choice for a Marine Drydock, providing a durable, high-performance solution that addresses the specific requirements of the environment. Its corrosion resistance, heavy-duty performance, safety features, and cost-effectiveness make it an indispensable asset for the rail yard’s ongoing success and operational efficiency.

Pultruded FRP Grating in other Industries:

Pultruded FRP grating is commonly used in various industries due to its superior strength, corrosion resistance, cold weather advantages and durability. Some potential industries where Pultruded T-5000 grating may be successfully implemented include:

- Marine and Offshore: Due to its corrosion resistance and durability, Pultruded FRP grating is suitable for marine and offshore applications, such as shipyards, docks, and offshore platforms.

- Industrial Manufacturing: Industries requiring heavy-duty flooring and grating solutions, such as manufacturing plants, chemical processing facilities, and industrial warehouses, can benefit from the high-strength and low-maintenance characteristics of Pultruded FRP grating.

- Transportation: The transportation sector, including railway facilities and infrastructure, can utilize Pultruded FRP grating for its durability and resistance to environmental factors.

- Construction and Infrastructure: In construction and infrastructure projects, Pultruded FRP grating can be used for walkways, platforms, and structural applications due to its high strength and corrosion resistance.

Characteristics of Pultruded FRP grating make it a versatile solution for a wide range of industries that require durable, corrosion-resistant, and high-strength grating products.

Why choose Pultruded FRP Grating?

Pultruded FRP (Fiber Reinforced Plastic) grating is often chosen over molded FRP grating or steel grating for industrial applications due to several key differences in their characteristics and performance. Here are the main reasons for choosing pultruded FRP grating:

Strength and Stiffness: Pultruded grating has a higher fiberglass concentration, making it stronger and stiffer than molded grating. This characteristic makes it suitable for applications requiring higher load-bearing capacity and longer spans.

Corrosion Resistance: Pultruded grating offers excellent corrosion resistance, making it ideal for harsh industrial environments where exposure to chemicals, moisture, and corrosive elements is a concern.

Heavy-Duty Applications: Due to its superior strength and load-bearing capabilities, pultruded grating is well-suited for heavy-duty industrial applications, such as manufacturing plants, chemical processing facilities, and offshore platforms.

Customization and Versatility: Pultruded grating can be customized to meet specific project requirements, offering versatility in panel sizes, resin systems, and other design features to accommodate various industrial applications.

Fire Retardant Properties: Some pultruded grating products are manufactured with fire retardant properties, making them suitable for applications where fire safety is a concern.

Pultruded FRP grating is preferred over molded grating for industrial applications due to its higher strength, stiffness, corrosion resistance, suitability for heavy-duty use, and the ability to be customized to meet specific project requirements.

Pultruded FRP VS Steel and Wood Grating

Pultruded FRP (Fiber Reinforced Plastic) grating is often chosen over steel grating for industrial applications due to several key advantages. Here are the main reasons for choosing pultruded FRP grating over steel grating:

- Corrosion Resistance: Pultruded FRP grating offers superior corrosion resistance compared to steel grating, making it ideal for corrosive environments, including chemical processing, marine, and industrial settings.

- Strength-to-Weight Ratio: Pultruded FRP grating provides high strength with a lower weight compared to steel, offering easier installation and reduced structural support requirements.

- Low Maintenance: FRP grating requires minimal maintenance and is resistant to chemicals, making it an attractive choice for industrial applications where exposure to water, chemicals, and cleaning agents is common.

- Safety Surface: The walking surface of pultruded grating often has a coarse epoxy grit bonded to the bearing bars, providing a safe surface for workers, even in wet conditions.

- Customization and Versatility: Pultruded FRP grating can be customized to meet specific project requirements, offering versatility in panel sizes, resin systems, and other design features to accommodate various industrial application.

Pultruded FRP grating is preferred over steel and wood grating for industrial applications due to its superior corrosion resistance, high strength-to-weight ratio, low maintenance requirements, safety features, and customization options. These advantages make it a versatile and cost-effective solution for a wide range of industrial settings.

Other Industries Utilizing Pultruded FRP Grating:

- chemical processing

- food & beverage

- marine

- aquatic centers

- oil & gas

- power

- manufacturing

- construction

- pharmaceutical

- metals & mining

- pulp & paper

- recreation

- water parks

- telecommunications

- shipping centers

- transportation facilities

- water & waste treatment