Posts

National Grating announces opening of new facility in Ontario with Grand Opening BBQ

/in alternative to steel grating, Barrie, Blog, Guelph, Hamilton, Kanata, Kingston, Kitchener, London, Milton, Niagara Falls, Ontario, Oshawa, St. Catharines, Toronto, Windsor /by Braden TaylorNational Grating is proud to announce the opening of its new location in Woodstock, Ontario, Canada with a BBQ for customers and suppliers. This strategic expansion is in response to the growing demand for FRP products and the company’s commitment to providing exceptional service to its customers.

“It was a great event for us to give back to our customers and suppliers who have helped us grow and get to where we are now. We really strive to provide our customers with the best customer service in the world and it was great to see so many of them at our Grand Opening BBQ.” Dylan Powell, National Grating Sales Director.

“We really owe our growth to our amazing customers. We aim to give them the best possible products and service so they can complete their projects with ease and efficiency, and provide their own customers with a quality experience.” Rick Van Rikxoort, National Grating President.

The new facility boasts a large inventory of FRP products, including bulk FRP molded and pultruded grating, as well as a wide range of specialty FRP solutions such as Stair Treads, Plate, Railing, Tubing, Beams, C-Channel, I-Beams, H-Beams and Threaded Rod and Nuts. With extensive inventory, National Grating is well-positioned to serve the needs of metal fabricators, contractors, and construction companies in Ontario and throughout North America. The company’s inventory and ability to ship quickly for projects, coupled with its custom fabrication services, make it a valuable partner for businesses seeking durable and versatile FRP solutions.

“National Grating is excited to bring our expertise and high-quality FRP products to Ontario,” said Dylan Powell, Sales Director at National Grating. “Our new location will allow us to better serve our customers in the region and provide them with the high quality FRP composite products they need, when they need them.”

The new facility will offer a complete line of non-slip, ADA compliant FRP solutions for various applications, including walkways and platform grating, railings, and stair treads.

National Grating’s FRP products are known for their corrosion resistance, significant weight savings, and ease of installation, making them an ideal alternative to traditional materials.

National Grating’s new location in Ontario is a testament to the company’s commitment to meeting the growing demand for FRP products in the region and across North America. With its extensive inventory and superior logistics network, the company is well-equipped to provide fast delivery of fiberglass grating to all major cities in Eastern Canada and the USA.

“National Grating has experienced huge growth over the past several years and has seen a need for an Eastern distribution hub to better serve our customers in the area. The massive amount of metal fabricators and contractors that have been switching over to our FRP solutions has really been the impetus for this new location and we look forward to providing them with the exceptional service that keeps our customers coming back.” Dylan Powell, National Grating Sales Director.

The new distribution center represents a significant step forward in furthering the company’s commitment to service and quality and strengthening the company’s ability to serve its valued customers. The opening of a new distribution centre also presents new job opportunities for locals in the area.

“We pride ourselves on providing the absolute best customer service in the industry with dedicated sales support, fast shipping, and a great product. Give us a call, talk to a real person about your projects FRP needs.” Rick van Rikxoort, National Grating President.

Highlights

- Bulk FRP Inventory: The new distribution center will stock a comprehensive inventory of bulk FRP molded and pultruded grating products, catering to the specific needs of metal fabricators and contractors in Eastern North America.

- Customer Service: National Grating is committed to providing expedited and reliable service, ensuring that customers have access to the products they need precisely when they need them.

- Enhanced Efficiency: The strategic location of the distribution center will significantly enhance the efficiency of product delivery, enabling National Grating to meet the demands of its Eastern region customers with unparalleled responsiveness.

National Grating Eastern Distribution Center Services

- Custom Fabrication Services:

- Our FRP experts are highly experienced in providing custom solutions to a variety of applications. Custom services are offered by the new National Grating location with an in-house fabrication shop and experienced professionals who work closely with clients to turn their design concepts into high-quality finished products.

- Bulk Inventory:

- National Grating specializes in having high levels of inventory on hand. This allows customers to view the product at our facility while also allowing us to quickly send samples and products to your office, factory, or construction site.

- On-site Training and Education:

- We are FRP experts with years of experience that we want to share. We believe our products and solutions and customer service is the best in the world and we want to share our expertise with you and your team. If you are interested in booking one of our local FRP experts to educate you and your team on FRP applications, uses and advantages please contact us at: 1-844-599-0260 or sales@nationalgrating.com

New Address:

684470 Road 68, Woodstock, ON, Canada, N0J 1A0

National Grating Fiberglass Reinforced Plastic (FRP) Solutions:

- Molded FRP Grating

- Pultruded FRP Grating

- Mini Mesh FRP Grating

- Heavy Duty / High Load Capacity FRP Grating

- Structural Shapes

- Stair Treads and Covers

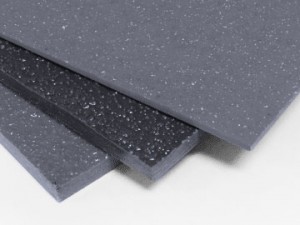

- Fiberglass Plate

- Fiberglass Tubing

- Fiberglass Railing

- Threaded Rod and Nuts

- Grating Clips

- Specialty Products

National Grating Customer Service

National Grating prides itself on providing exceptional customer service to all customers, big and small.

Reach out to us today for your next FRP Project!

Sales@NationalGrating.com / 1-844-599-0260

National Grating Newsletter

Every month we send our National Grating family a quick update on exciting new things that are happening with us. We touch on exciting new projects, new products and interesting new applications of our products. Welcome to the family!

National Grating FRP Solutions Increase Safety

/in Blog, Fiberglass Grating /by Braden TaylorJune is National Safety Month – the annual observance to help keep each other safe from the workplace to anyplace.

National Grating prioritizes safety at our own facilities as well as with our customers’ projects. We believe our products and solutions can help to make your projects safer so that we can all go home to our families at the end of the day.

In 2021-22 the National Safety Council counted 450,540 injuries in the USA related to slips, trips and falls. This translates to an injury rate of 22.6 per 10,000 full-time workers. With slips, trips and falls being one of the biggest causes of workplace injury, we are dedicated to doing more to ensure workspaces are safe.

National Grating prides itself on offering products that can improve the safety of workplaces everywhere. Below we go into more detail about how National Grating FRP Solutions increase safety.

National Grating FRP Solutions are Anti Slip

Our anti slip Molded and Pultruded Grating products are designed to ensure walking surfaces are not slippery and hazardous.

FRP products such as non-slip treads, nosings, and grating, provide excellent traction. This minimizes the risk of slips, trips, and falls, especially in areas prone to wetness, spills or snow and ice.

We created a related article about Winter Applications for FRP Grating, Stair Treads and Railings

National Grating FRP Solutions use High Contrast Colours for Safety

Our FRP Stair Treads and Stair Tread Covers combine anti-slip coatings with high contrast yellow nosings for high visibility.

National Grating FRP Solutions are Lightweight and Safe

Worker Safety:

The lightweight nature of FRP products reduces injuries associated with lifting and handling heavy materials during transportation, installation and maintenance.

National Grating FRP Solutions are Long Lasting

Longevity:

FRP won’t rust, corrode, or attract insects, ensuring a steady surface for workers over time.

National Grating FRP Solutions are Impact Resistant

FRP grating withstands impact, reducing the risk of dents or tripping hazards caused by dropped tools or heavy items.

National Grating FRP Solutions are Non-Conductive

Unlike metal systems, FRP grating doesn’t conduct electricity. This helps prevent electric shocks. FRP is an excellent and safe choice for all applications involving the risk of electrocution.

National Grating FRP Solutions do not require welding

With FRP products there is no need for welding which reduces potential safety risks. Welding involves working with highly heated metal and sparks, making burns and fires a significant safety risk. FRP Products are simply fastened with nuts, bolts, washers, and clips.

National Grating FRP Solutions reduce liability

Liability Reduction: By proactively minimizing accidents, businesses can lower their liability and associated costs.

National Grating FRP Solutions have Extreme Hot and Cold Resistance

Cold Resistance:

- Non-Conductive: In harsh weather environments like extreme cold FRP Products won’t adhere to skin. Unlike steel, FRP doesn’t conduct heat, making it safe to touch even in arctic applications.

- Mechanical Strength: FRP retains its strength at low temperatures, unlike some metals that become brittle.

Hot Resistance:

- Thermal Stability: FRP maintains its structural integrity at high temperatures.

- Low Thermal Expansion: Unlike metals, FRP has minimal expansion and contraction with temperature changes.

- Fire Resistance: FRP doesn’t burn easily and has low heat conductivity.

National Grating Fiberglass Reinforced Plastic (FRP) Solutions:

- Molded FRP Grating

- Pultruded FRP Grating

- Mini Mesh FRP Grating

- Heavy Duty / High Load Capacity FRP Grating

- Structural Shapes

- Stair Treads and Covers

- Fiberglass Plate

- Fiberglass Tubing

- Fiberglass Railing

- Threaded Rod and Nuts

- Grating Clips

- Specialty Products

National Grating Customer Service

National Grating prides itself on providing exceptional customer service to all customers, big and small.

Reach out to us today for your next FRP Project!

Sales@NationalGrating.com / 1-844-599-0260

National Grating Newsletter

Every month we send our National Grating family a quick update on exciting new things that are happening with us. We touch on exciting new projects, new products and interesting new applications of our products. Welcome to the family!

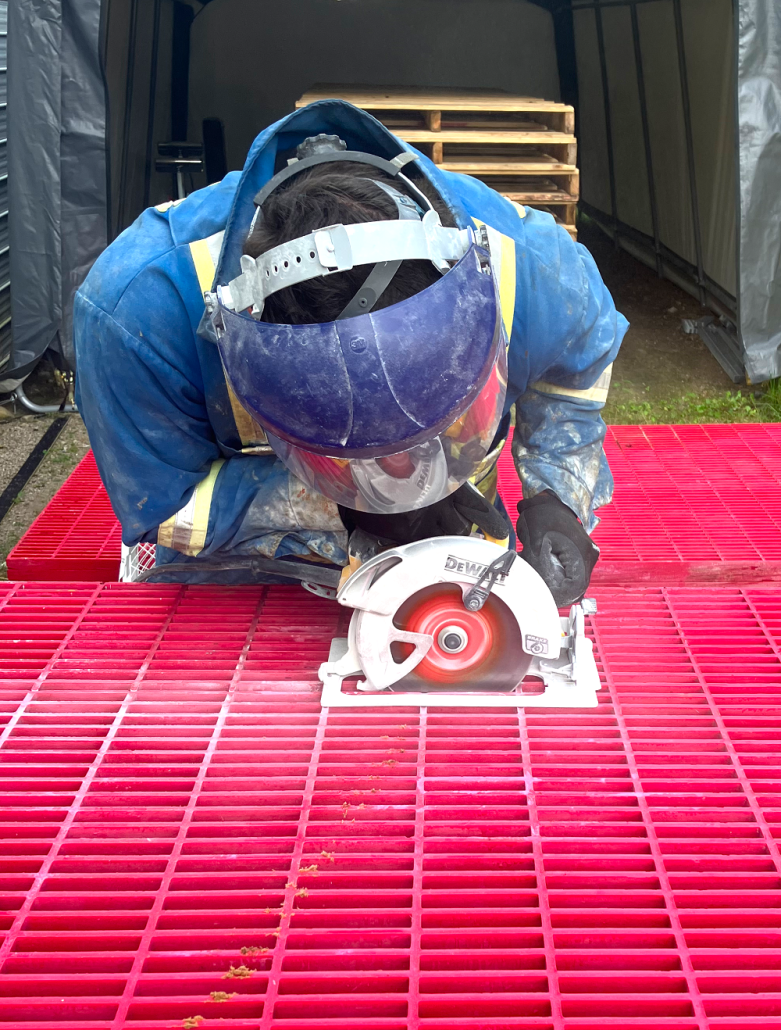

National Grating offers custom colour & custom size FRP Solutions

/in Blog, Fiberglass Grating /by Braden TaylorNational Grating is a leading supplier of Fiberglass Reinforced Plastic (FRP) products in North America. National Grating specializes in FRP solutions, including custom FRP Molded Grating, Pultruded Grating, FRP Beams and Angles and FRP Stair Treads and FRP Stair Tread Covers. These products come in various shapes and colours and can be ordered with custom colours and sizes to fit specific project requirements.

National Grating keeps standard FRP items in stock for fast delivery and can accommodate custom-coloured FRP solutions as well.

Request a quote for custom FRP Solutions

Custom Colours

National Grating stocks high levels of grey and yellow grating and structural products while also having the ability to provide custom colours upon request.

Why should you choose custom coloured FRP solutions?

Branding and Identity: Reinforce your brand identity by choosing custom colours that match your logo and brand design.

Project-Specific Requirements: Each project is unique. National Grating offers customization and flexibility to meet the specific requirements of your project.

Aesthetics: Standard gray and yellow colouring isn’t for everyone. Custom colours help make your design concept a reality. Whether it’s for architectural elements, walkways, or industrial applications, colour customization enhances the visual appeal of your space and takes your project from ordinary to exceptional.

Safety and Visibility: Different colours can be used to indicate specific areas or hazards. For example:

- Safety Yellow: Used for walkways, stairs, and platforms to highlight safe paths.

- Red or Orange: Indicates caution or danger zones.

- Green: Often used for escape routes or emergency exits.

Custom Sizes

National Grating stocks high levels of 3’x10′, 4’x8′, 4’x10′, 4’x12′ and 5’x10, 5’x12 panels and 20′ structural products like beam and angle while also providing custom sizes of grating and structural products.

Why do customers want custom sizes of FRP solutions?

Tailored Fit: Custom-cut grating ensures a precise fit for specific areas or irregular shapes. It allows you to match the grating to existing structures or equipment.

Replacement: When replacing damaged sections of existing grating, custom cuts ensure seamless integration without compromising structural integrity.

Pipe Penetrations: Custom cuts accommodate pipe or equipment penetrations without additional support.

Remember to consider load requirements, chemical resistance, and slip resistance when selecting FRP grating. Consult with our FRP experts for the right configuration!

National Grating Newsletter

Every month we send our National Grating family a quick update on exciting new things that are happening with us. We touch on exciting new projects, new products and interesting new applications of our products. Welcome to the family!

National Grating Customer Service

National Grating prides itself on providing exceptional customer service to all customers, big and small.

Reach out to us today for your next FRP Project!

Sales@NationalGrating.com / 1-844-599-0260

National Grating Fiberglass Reinforced Plastic (FRP) Solutions:

National Grating FRP Solutions Application Profile – FRP Molded Grating Marina Decking

/in Blog, Fiberglass Grating /by Braden Taylor

Project

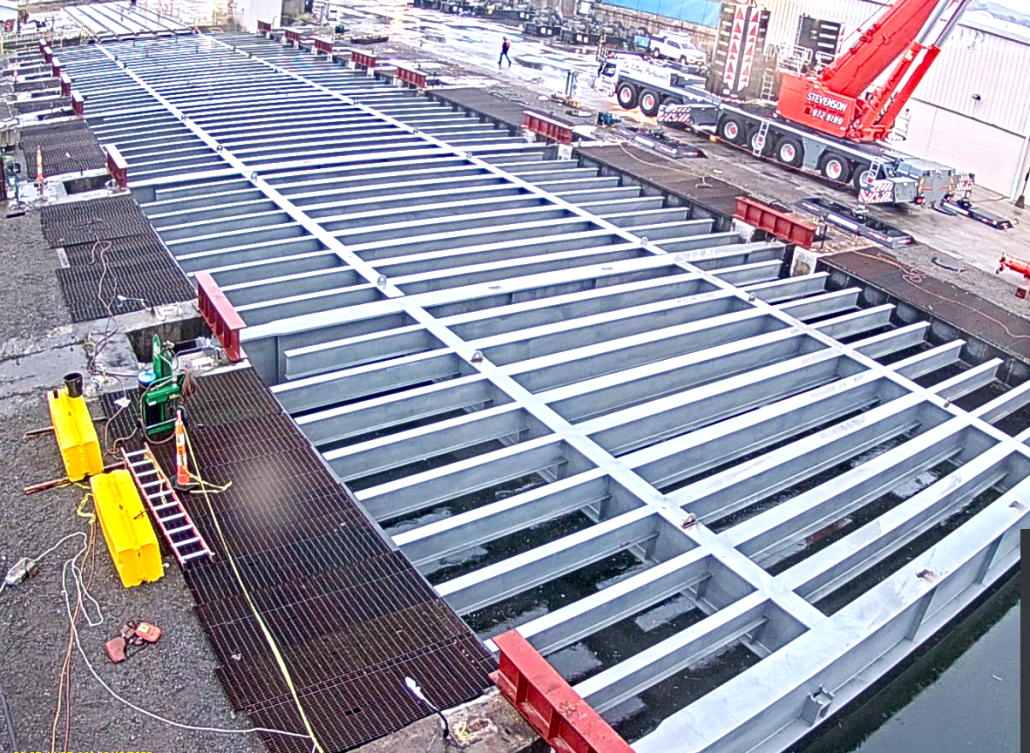

110 FT of National Grating FRP Molded Grating Marina decking installed in a Pacific Ocean Marina.

A marina on the Pacific Coast of British Columbia required 110ft of dock to be replaced. The contractor decided to contact National Grating to explore FRP Solutions. They decided on Grey Molded FRP Grating with 1.5” gaps to replace the decking section of this dock.

National Grating FRP Solution

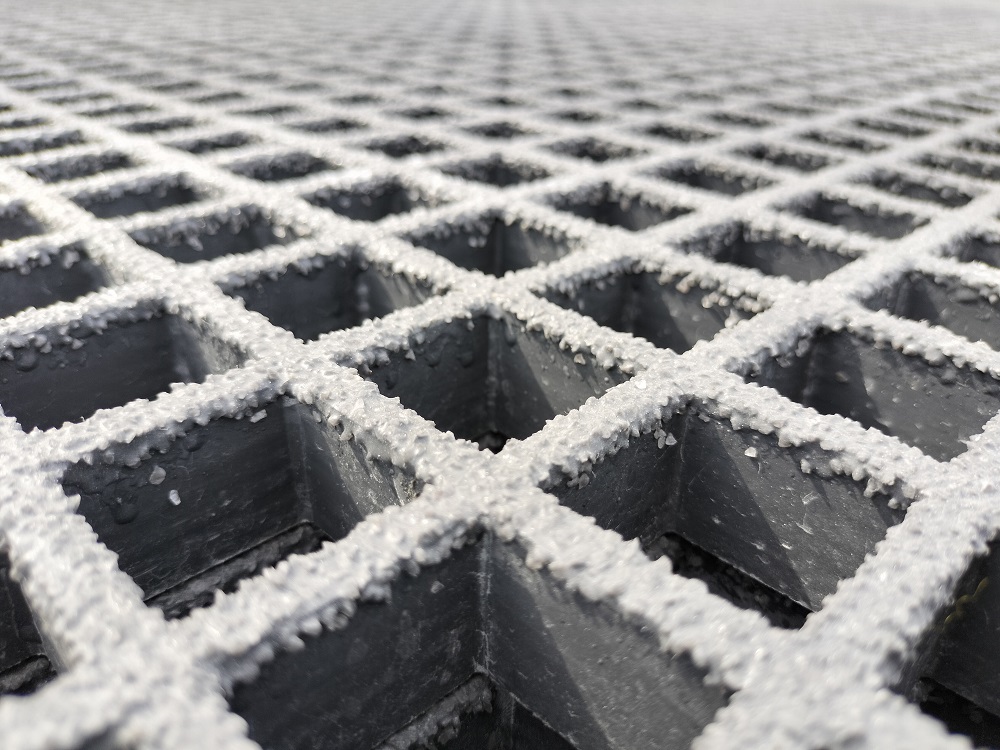

Grey Molded FRP Grating with 1.5” x 1.5” gaps with gritted top coating for added slip resistance in wet environment.

Why was Molded FRP Grating Chosen?

Molded FRP Grating from National Grating was perfect for this application because of its anti-corrosion properties, durability, strength and lightweight nature, and its ability to let sun and water pass through the grating.

Corrosion Resistance

FRP grating is highly resistant to corrosion, making it durable in harsh marine environments.

Anti-Slip Properties

The concave and anti-slip grit surface provides excellent anti-slip properties, ensuring safety for pedestrians, even in wet conditions.

Durability and Longevity

FRP grating is highly durable, resistant to saltwater, UV rays, and corrosion, making it ideal for marine environments.

Strength and Durability

FRP grating is engineered to withstand heavy loads making it ideal for docks and marinas. FRP Grating has a high strength to weight ratio allowing for a strong structure that is also lightweight. While comparable in strength, FRP grating is significantly lighter than steel, making it easier to install without heavy lifting equipment.

Open Area

The open area of Molded FRP Grating is an important factor in environmental sustainability, allowing sun to pass through to plants, seagrass, and other shallow marine habitats beneath the decking surface.

During storms the open area also allows wind and water to pass through lessening the stress on the dock structure and mounting hardware.

National Grating Dock and Marina FRP Solutions

Common sheet sizes for Molded FRP grating include: 4’x8′, 4’x12′, and 3’x10′. Common thicknesses include: 1″, 1.5″ and 2″.

Fiberglass Grating pultrusion’s come in three categories: I-Shape bars, T-Shape bars, and High-Load bars for heavy duty applications. The bearing bars are interconnected with cross-rods every 6 inches.

Mini-Mesh fiberglass grating has a ¾” grid pattern with ½” open squares. This results in 44% open area which allows light and water to pass through and provides a very comfortable decking surface to walk on in bare feet.

Stair Treads and Covers

Fiberglass stair treads are available as molded FRP treads with yellow nosings and a gritted surface, for the ultimate in safety.

Fiberglass stairs are the best solution for outdoor anti-slip stairs. They outlast traditional building materials and are easy to install. Stair treads made of FRP grating are lightweight, easy to fabricate, and highly durable.

National Grating Fiberglass Reinforced Plastic (FRP) Solutions:

- Molded FRP Grating

- Pultruded FRP Grating

- Mini Mesh FRP Grating

- Heavy Duty / High Load Capacity FRP Grating

- Structural Shapes

- Stair Treads and Covers

- Fiberglass Plate

- Fiberglass Tubing

- Fiberglass Railing

- Threaded Rod and Nuts

- Grating Clips

- Specialty Products

National Grating Newsletter

Every month we send our National Grating family a quick update on exciting new things that are happening with us. We touch on exciting new projects, new products and interesting new applications of our products. Welcome to the family!

National Grating Customer Service

National Grating prides itself on providing exceptional customer service to all customers, big and small.

Reach out to us today for your next FRP Project!

Sales@NationalGrating.com / 1-844-599-0260

Eco Benefits and Sustainability of FRP Grating

/in Blog /by Braden Taylor

Green energy and decarbonization policies aim to reduce emissions and transition to more efficient use of our energy. One area that can contribute to this goal is using environmentally friendly materials and technologies in the construction and maintenance of infrastructure. One such material is fiberglass reinforced plastic (FRP) grating, which has several benefits over traditional steel grating.

FRP has a Low Carbon Footprint

FRP grating has a much lower carbon footprint compared to steel grating. Steel is an energy intensive material that requires a lot of energy to manufacture, transport, and install. In contrast, FRP grating is made from a combination of lightweight and durable materials such as fiberglass and resin. As a result, the production and use of FRP grating can significantly reduce carbon emissions.

FRP is Lightweight

FRP grating is much lighter than steel grating, which means it requires less energy to transport and install. This can result in significant energy savings, especially in cases where large quantities of grating need to be transported and installed over long distances.

FRP does not Corrode

Furthermore, FRP grating is corrosion-resistant and requires less maintenance compared to steel grating. This means that it has a longer lifespan, reducing the need for replacement and therefore further reducing carbon emissions and energy consumption and can be re-used, re-purposed and re-cycled.

Eco Benefits & Sustainability FRP Grating

In conclusion, the use of FRP grating in infrastructure projects can have significant sustainability benefits for reducing carbon emissions and energy consumption. By choosing FRP grating over traditional steel grating, governments and businesses can contribute to their green energy and decarbonization goals while still maintaining the high-quality and durable infrastructure that is necessary for economic growth and development.

National Grating Fiberglass Reinforced Plastic (FRP) Solutions:

- Molded FRP Grating

- Pultruded FRP Grating

- Mini Mesh FRP Grating

- Heavy Duty / High Load Capacity FRP Grating

- Structural Shapes

- Stair Treads and Covers

- Fiberglass Plate

- Fiberglass Tubing

- Fiberglass Railing

- Threaded Rod and Nuts

- Grating Clips

- Specialty Products

National Grating Customer Service

National Grating prides itself on providing exceptional customer service to all customers, big and small.

Reach out to us today for your next FRP Project!

Sales@NationalGrating.com / 1-844-599-0260

Is Fiberglass Reinforced FRP Grating better than Steel Grating?

/in Blog, Fiberglass Grating, Floor Grating, FRP Grating, FRP Plate, FRP Supplier, FRP Walkways for Marinas /by Braden Taylor

At National Grating we believe Fiberglass Reinforced FRP Grating is far superior than steel grating.

For decades National Grating has been providing FRP Solutions in the form of Molded, Pultruded, Mini Mesh and High Load Capacity Grating and FRP Structural Shapes like C-Channel, I-Beams, Tubing and Stair Treads to customers across North America.

Our years of experience in this industry provide the in-depth technical knowledge required to select the FRP material that meets the needs of your project.

We are continually improving our line of fiberglass products with the latest innovations to provide our customers with the most cost-effective, high quality FRP solutions. We also take pride in superior technical support, giving you the information you need to confidently make the right choice.

Here is why we believe FRP Grating and FRP Solutions are far better than steel grating alternatives.

Strength:

Fiberglass grating offers comparable strength to steel but with added benefits like improved impact resistance and flexibility.

While comparable in strength, FRP grating is significantly lighter than steel, making it easier to install without heavy lifting equipment.

Corrosion Resistance:

FRP grating excels in corrosive environments as it does not rust or corrode like steel, making it ideal for use around chemicals or outdoor elements corrosive to steel.

Safety:

Fiberglass grating is non-conductive, providing safety benefits in electrically hazardous workplaces. It also offers slip resistance and is softer underfoot compared to steel, reducing worker fatigue.

Cost:

While the production cost of FRP grating is higher than steel, the long-term maintenance-free aspect of FRP can make it a more cost-effective choice over time. Steel grating requires ongoing maintenance and replacement costs.

Long Life Span:

FRP does not rust or rot and does not degrade due to sun exposure, moisture and humidity, or extreme heat and cold.

Maintenance Free:

FRP grating requires little-to-no maintenance costs post-installation, unlike steel grating that may need regular maintenance.

FRP Grating has optional colors that are added during the molding process which instills the entire product with a consistent color that does not wear out or rub off. Unlike steel grating that is painted that can wear off over time requiring maintenance.

The advantages of FRP grating over steel include its strength, lightweight nature, corrosion resistance, non-conductivity, safety features, and cost-effectiveness in the long run.

National Grating Customer Service

National Grating prides itself on providing exceptional customer service to all customers, big and small.

Reach out to us today for your next FRP Project!

Sales@NationalGrating.com / 1-844-599-0260

National Grating Fiberglass Reinforced Plastic (FRP) Grating Solutions:

Fiberglass FRP Grating for Car Washes and Vehicle Maintenance Facilities

/in alternative to steel grating, Blog, car wash, Fiberglass Grating, Floor Grating, FRP Grating /by Braden TaylorFiberglass FRP Grating is the perfect solution for Car Wash and Vehicle Maintenance facilities like mechanics and oil changers.

National Grating is a leading supplier of FRP solutions for car wash and vehicle maintenance facilities across North America.

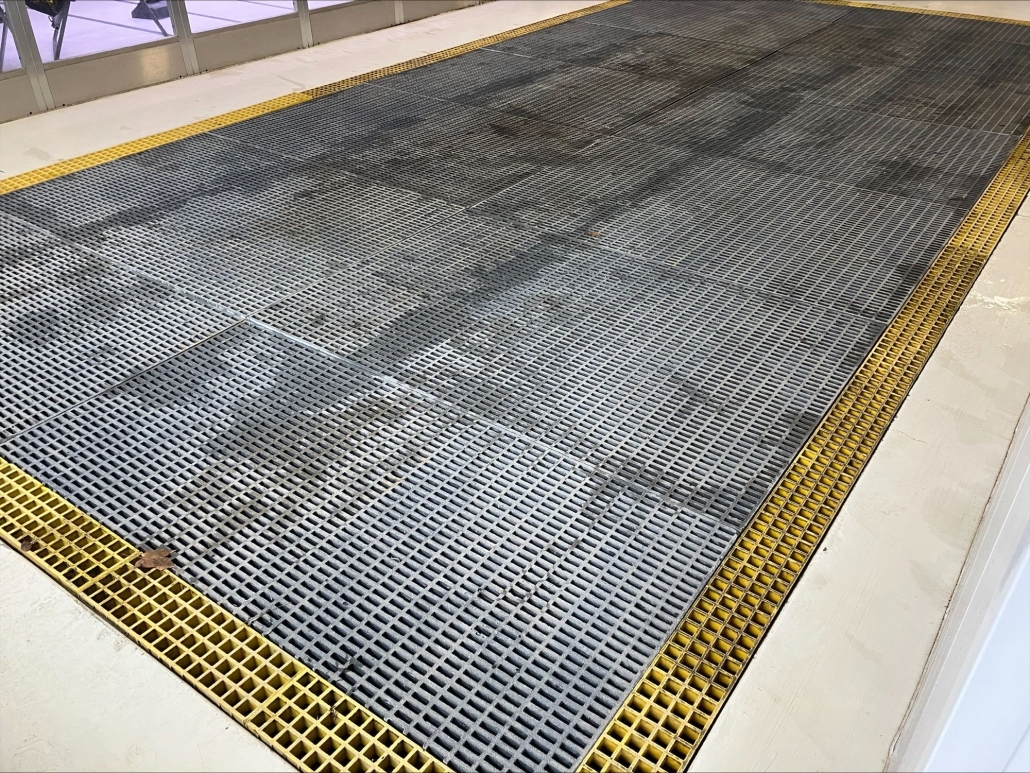

FRP Grating uses in Car Wash facilities

Fiberglass FRP Solutions are used in Car Wash facilities primarily as grating for water drainage and in Mechanics for Oils, coolant, and other liquid drainage. The molded or pultruded FRP grating is often used to span a drainage ditch to allow liquids to flow into a drainage system while providing a strong and safe surface for vehicles and customers. For heavy loads High Load Capacity (HLC) or Heavy-Duty FRP Grating is used that can support vehicle weights.

Other FRP applications in vehicle maintenance facilities include grating for walkways, FRP Stair Treads for nonslip stairs, FRP plate for a solid nonslip surface on platforms or walking surfaces and FRP Railing for noncorrosive hand railings.

- Wash Bays

- Troughs

- Drainage Systems

- Trenches

- Walkways

- Grating

- Platforms

- Nonslip stairs

- Railing

National Grating FRP Solutions for Car Washes:

- Molded & Pultruded Grating

- Drainage trenches, flooring, platforms, walkways.

- FRP grating is utilized in car washes for its drainage capabilities, safety features, aesthetic appeal, ease of maintenance, and chemical resistance, making it a versatile and practical solution for flooring and drainage needs in these facilities.

- Heavy Duty Grating

- Engineered to carry heavy traffic like cars, trucks & forklifts.

- Heavy Duty HLC (High Load Capacity) FRP grating is used in car washes due to its strength, durability, corrosion resistance, low maintenance requirements, safety features, and ease of installation, making it an ideal choice for areas with heavy vehicle traffic like those found in car wash facilities.

- FRP Stair Treads and Covers

- Slip-resistant & durable stair solutions.

- FRP stair treads are utilized in car washes for their non-slip properties, corrosion resistance, durability, and ease of maintenance, making them a practical and safe choice for stairs within these facilities.

- FRP Plate

- Resistant to soap, chemicals & water.

- FRP plates are utilized in car washes due to their corrosion resistance, durability, ease of maintenance, and safety features, making them a suitable choice for various applications within these facilities.

Why FRP Grating is perfect for Car Washes:

Durability: FRP grating is commonly used in car wash drains due to its corrosion resistance, durability, and ability to handle heavy traffic and exposure to water and chemicals without deteriorating or requiring frequent replacements.

Corrosion Resistance: FRP materials are resistant to corrosion from water and cleaning chemicals commonly used in car wash operations, ensuring longevity even in harsh environments.

Chemical Resistant: FRP grating is resistant to chemicals commonly used in car wash operations, making it a suitable choice for areas exposed to cleaning agents and detergents without deteriorating or losing its structural integrity.

Non-slip: The non-slip properties of FRP grating make it a safe flooring option for car wash facilities, providing traction even when wet and reducing the risk of slips and falls for both customers and staff.

Strength and Durability: HLC grating is engineered to withstand heavy vehicle traffic, including forklifts and large trucks, making it ideal for areas with high loads like car wash facilities. It is extremely durable and can handle corrosive environments without rusting, ensuring a long-lasting solution.

Safety and Performance: The high strength-to-weight ratio of HLC grating makes it easy to handle and install, providing a safe and stable flooring solution for car wash areas with heavy traffic. Its non-conductive properties also enhance safety in these environments.

Easy Maintenance: FRP Grating is easy to clean and maintain, requiring minimal effort to keep it looking new and ensuring a hygienic environment.

FRP grating is utilized in car washes for its drainage capabilities, safety features, aesthetic appeal, ease of maintenance, and chemical resistance, making it a versatile and practical solution for flooring and drainage needs in these facilities.

National Grating Fiberglass Reinforced Plastic (FRP) Grating Solutions:

- Molded FRP Grating

- Pultruded FRP Grating

- Heavy Duty / High Load Capacity FRP Grating

- Structural Shapes

- Stair Treads and Covers

- Fiberglass Plate

- Fiberglass Tubing

- Fiberglass Railing

- Threaded Rod and Nuts

- Grating Clips

- Specialty Products

National Grating Customer Service

National Grating prides itself on providing exceptional customer service to all customers, big and small.

Reach out to us today for your next FRP Project!

Sales@NationalGrating.com / 1-844-599-0260

Pultruded FRP Grating: The Ideal Solution for Canadian Marine Dry Docks and Rail Yards

/in Alberta, alternative to steel grating, B.C., Blog, Dock Repair, Fiberglass Grating, Fiberglass Railing, Fiberglass Walkway, marina walkways, Ontario, Pultruded Grating /by Braden TaylorNational Grating has been seeing high levels of interest in Pultruded FRP Grating for applications such as Marine Dry Docks across Canada, North America and even as far north as Alaska due to its winter advantages.

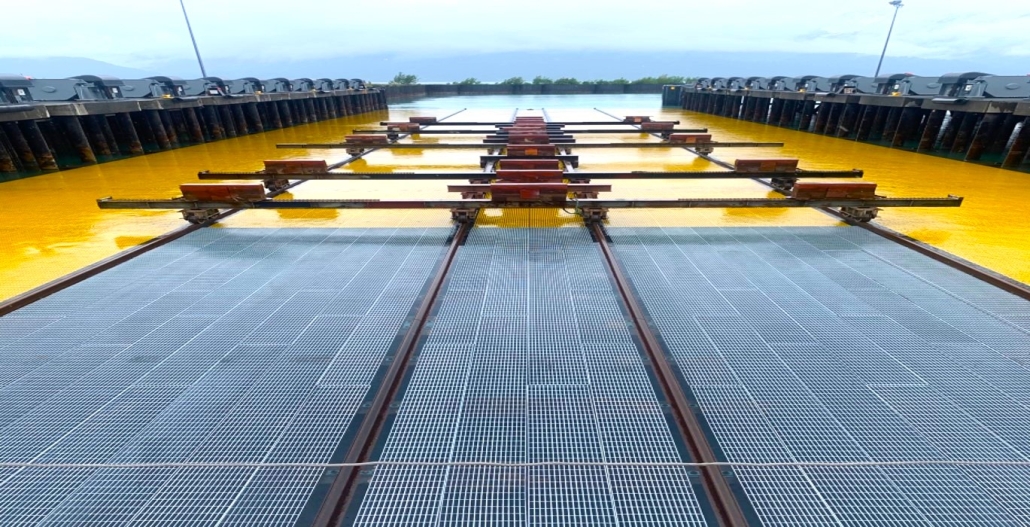

This Marine Towing Drydock operating in the Great Lakes has found the perfect solution for its demanding environment with the implementation of Pultruded T-5000 FRP Grating from National Grating. This innovative grating, engineered from fiberglass-reinforced plastic (FRP), offers a comprehensive set of advantages that address the specific needs of the rail yard, ensuring enhanced performance and durability.

Corrosion Resistance and Longevity

Pultruded FRP Grating is designed to withstand the harshest environments, making it an ideal choice for the Marine Towing Drydock Rail Yard. Its superior corrosion resistance, surpassing traditional materials such as stainless steel, aluminum, and galvanized gratings, ensures longevity and minimizes maintenance requirements.

Heavy-Duty Performance

Engineered to carry higher loads, Pultruded T-5000 Grating delivers exceptional strength and stiffness, making it well-suited for the rigorous demands of the rail yard. Its heavy-duty design provides the necessary support for various operational activities, contributing to a reliable and robust infrastructure.

Safety and Efficiency

The safety surface of Pultruded T-5000 Grating, featuring a coarse epoxy grit, enhances worker safety, even in challenging conditions. This prioritization of safety aligns with the dry docks commitment to maintaining a secure working environment for its personnel.

Low Maintenance and Cost-Effectiveness

The implementation of Pultruded T-5000 Grating offers the Marine Towing Drydock Rail Yard a low-maintenance solution, reducing the need for frequent repairs and upkeep. Furthermore, its cost-effectiveness and long-term performance make it a valuable investment for the rail yard’s operational infrastructure.

Pultruded Grating stands as the optimal choice for a Marine Drydock, providing a durable, high-performance solution that addresses the specific requirements of the environment. Its corrosion resistance, heavy-duty performance, safety features, and cost-effectiveness make it an indispensable asset for the rail yard’s ongoing success and operational efficiency.

Pultruded FRP Grating in other Industries:

Pultruded FRP grating is commonly used in various industries due to its superior strength, corrosion resistance, cold weather advantages and durability. Some potential industries where Pultruded T-5000 grating may be successfully implemented include:

- Marine and Offshore: Due to its corrosion resistance and durability, Pultruded FRP grating is suitable for marine and offshore applications, such as shipyards, docks, and offshore platforms.

- Industrial Manufacturing: Industries requiring heavy-duty flooring and grating solutions, such as manufacturing plants, chemical processing facilities, and industrial warehouses, can benefit from the high-strength and low-maintenance characteristics of Pultruded FRP grating.

- Transportation: The transportation sector, including railway facilities and infrastructure, can utilize Pultruded FRP grating for its durability and resistance to environmental factors.

- Construction and Infrastructure: In construction and infrastructure projects, Pultruded FRP grating can be used for walkways, platforms, and structural applications due to its high strength and corrosion resistance.

Characteristics of Pultruded FRP grating make it a versatile solution for a wide range of industries that require durable, corrosion-resistant, and high-strength grating products.

Why choose Pultruded FRP Grating?

Pultruded FRP (Fiber Reinforced Plastic) grating is often chosen over molded FRP grating or steel grating for industrial applications due to several key differences in their characteristics and performance. Here are the main reasons for choosing pultruded FRP grating:

Strength and Stiffness: Pultruded grating has a higher fiberglass concentration, making it stronger and stiffer than molded grating. This characteristic makes it suitable for applications requiring higher load-bearing capacity and longer spans.

Corrosion Resistance: Pultruded grating offers excellent corrosion resistance, making it ideal for harsh industrial environments where exposure to chemicals, moisture, and corrosive elements is a concern.

Heavy-Duty Applications: Due to its superior strength and load-bearing capabilities, pultruded grating is well-suited for heavy-duty industrial applications, such as manufacturing plants, chemical processing facilities, and offshore platforms.

Customization and Versatility: Pultruded grating can be customized to meet specific project requirements, offering versatility in panel sizes, resin systems, and other design features to accommodate various industrial applications.

Fire Retardant Properties: Some pultruded grating products are manufactured with fire retardant properties, making them suitable for applications where fire safety is a concern.

Pultruded FRP grating is preferred over molded grating for industrial applications due to its higher strength, stiffness, corrosion resistance, suitability for heavy-duty use, and the ability to be customized to meet specific project requirements.

Pultruded FRP VS Steel and Wood Grating

Pultruded FRP (Fiber Reinforced Plastic) grating is often chosen over steel grating for industrial applications due to several key advantages. Here are the main reasons for choosing pultruded FRP grating over steel grating:

- Corrosion Resistance: Pultruded FRP grating offers superior corrosion resistance compared to steel grating, making it ideal for corrosive environments, including chemical processing, marine, and industrial settings.

- Strength-to-Weight Ratio: Pultruded FRP grating provides high strength with a lower weight compared to steel, offering easier installation and reduced structural support requirements.

- Low Maintenance: FRP grating requires minimal maintenance and is resistant to chemicals, making it an attractive choice for industrial applications where exposure to water, chemicals, and cleaning agents is common.

- Safety Surface: The walking surface of pultruded grating often has a coarse epoxy grit bonded to the bearing bars, providing a safe surface for workers, even in wet conditions.

- Customization and Versatility: Pultruded FRP grating can be customized to meet specific project requirements, offering versatility in panel sizes, resin systems, and other design features to accommodate various industrial application.

Pultruded FRP grating is preferred over steel and wood grating for industrial applications due to its superior corrosion resistance, high strength-to-weight ratio, low maintenance requirements, safety features, and customization options. These advantages make it a versatile and cost-effective solution for a wide range of industrial settings.

Other Industries Utilizing Pultruded FRP Grating:

- chemical processing

- food & beverage

- marine

- aquatic centers

- oil & gas

- power

- manufacturing

- construction

- pharmaceutical

- metals & mining

- pulp & paper

- recreation

- water parks

- telecommunications

- shipping centers

- transportation facilities

- water & waste treatment

Resources

Popular Pages

FRP Specs & Topics

- National Grating announces new FRP location in Edmonton, Alberta!

- National Grating Offers Custom Cutting and Fabrication of FRP Solutions

- National Grating announces opening of new facility in Ontario with Grand Opening BBQ

- FRP Solutions for Rooftop Walkways

- National Grating FRP Solutions Increase Safety

Customer Support

or call us toll free:

1-844.599.0260

#102 - 5041 Regent St.Burnaby, BC V5C 4H4 Canada