National Grating announces opening of new facility in Ontario with Grand Opening BBQ

/in alternative to steel grating, Barrie, Blog, Guelph, Hamilton, Kanata, Kingston, Kitchener, London, Milton, Niagara Falls, Ontario, Oshawa, St. Catharines, Toronto, Windsor /by Braden TaylorNational Grating is proud to announce the opening of its new location in Woodstock, Ontario, Canada with a BBQ for customers and suppliers. This strategic expansion is in response to the growing demand for FRP products and the company’s commitment to providing exceptional service to its customers.

“It was a great event for us to give back to our customers and suppliers who have helped us grow and get to where we are now. We really strive to provide our customers with the best customer service in the world and it was great to see so many of them at our Grand Opening BBQ.” Dylan Powell, National Grating Sales Director.

“We really owe our growth to our amazing customers. We aim to give them the best possible products and service so they can complete their projects with ease and efficiency, and provide their own customers with a quality experience.” Rick Van Rikxoort, National Grating President.

The new facility boasts a large inventory of FRP products, including bulk FRP molded and pultruded grating, as well as a wide range of specialty FRP solutions such as Stair Treads, Plate, Railing, Tubing, Beams, C-Channel, I-Beams, H-Beams and Threaded Rod and Nuts. With extensive inventory, National Grating is well-positioned to serve the needs of metal fabricators, contractors, and construction companies in Ontario and throughout North America. The company’s inventory and ability to ship quickly for projects, coupled with its custom fabrication services, make it a valuable partner for businesses seeking durable and versatile FRP solutions.

“National Grating is excited to bring our expertise and high-quality FRP products to Ontario,” said Dylan Powell, Sales Director at National Grating. “Our new location will allow us to better serve our customers in the region and provide them with the high quality FRP composite products they need, when they need them.”

The new facility will offer a complete line of non-slip, ADA compliant FRP solutions for various applications, including walkways and platform grating, railings, and stair treads.

National Grating’s FRP products are known for their corrosion resistance, significant weight savings, and ease of installation, making them an ideal alternative to traditional materials.

National Grating’s new location in Ontario is a testament to the company’s commitment to meeting the growing demand for FRP products in the region and across North America. With its extensive inventory and superior logistics network, the company is well-equipped to provide fast delivery of fiberglass grating to all major cities in Eastern Canada and the USA.

“National Grating has experienced huge growth over the past several years and has seen a need for an Eastern distribution hub to better serve our customers in the area. The massive amount of metal fabricators and contractors that have been switching over to our FRP solutions has really been the impetus for this new location and we look forward to providing them with the exceptional service that keeps our customers coming back.” Dylan Powell, National Grating Sales Director.

The new distribution center represents a significant step forward in furthering the company’s commitment to service and quality and strengthening the company’s ability to serve its valued customers. The opening of a new distribution centre also presents new job opportunities for locals in the area.

“We pride ourselves on providing the absolute best customer service in the industry with dedicated sales support, fast shipping, and a great product. Give us a call, talk to a real person about your projects FRP needs.” Rick van Rikxoort, National Grating President.

Highlights

- Bulk FRP Inventory: The new distribution center will stock a comprehensive inventory of bulk FRP molded and pultruded grating products, catering to the specific needs of metal fabricators and contractors in Eastern North America.

- Customer Service: National Grating is committed to providing expedited and reliable service, ensuring that customers have access to the products they need precisely when they need them.

- Enhanced Efficiency: The strategic location of the distribution center will significantly enhance the efficiency of product delivery, enabling National Grating to meet the demands of its Eastern region customers with unparalleled responsiveness.

National Grating Eastern Distribution Center Services

- Custom Fabrication Services:

- Our FRP experts are highly experienced in providing custom solutions to a variety of applications. Custom services are offered by the new National Grating location with an in-house fabrication shop and experienced professionals who work closely with clients to turn their design concepts into high-quality finished products.

- Bulk Inventory:

- National Grating specializes in having high levels of inventory on hand. This allows customers to view the product at our facility while also allowing us to quickly send samples and products to your office, factory, or construction site.

- On-site Training and Education:

- We are FRP experts with years of experience that we want to share. We believe our products and solutions and customer service is the best in the world and we want to share our expertise with you and your team. If you are interested in booking one of our local FRP experts to educate you and your team on FRP applications, uses and advantages please contact us at: 1-844-599-0260 or sales@nationalgrating.com

New Address:

684470 Road 68, Woodstock, ON, Canada, N0J 1A0

National Grating Fiberglass Reinforced Plastic (FRP) Solutions:

- Molded FRP Grating

- Pultruded FRP Grating

- Mini Mesh FRP Grating

- Heavy Duty / High Load Capacity FRP Grating

- Structural Shapes

- Stair Treads and Covers

- Fiberglass Plate

- Fiberglass Tubing

- Fiberglass Railing

- Threaded Rod and Nuts

- Grating Clips

- Specialty Products

National Grating Customer Service

National Grating prides itself on providing exceptional customer service to all customers, big and small.

Reach out to us today for your next FRP Project!

Sales@NationalGrating.com / 1-844-599-0260

National Grating Newsletter

Every month we send our National Grating family a quick update on exciting new things that are happening with us. We touch on exciting new projects, new products and interesting new applications of our products. Welcome to the family!

Fiberglass FRP Grating for Car Washes and Vehicle Maintenance Facilities

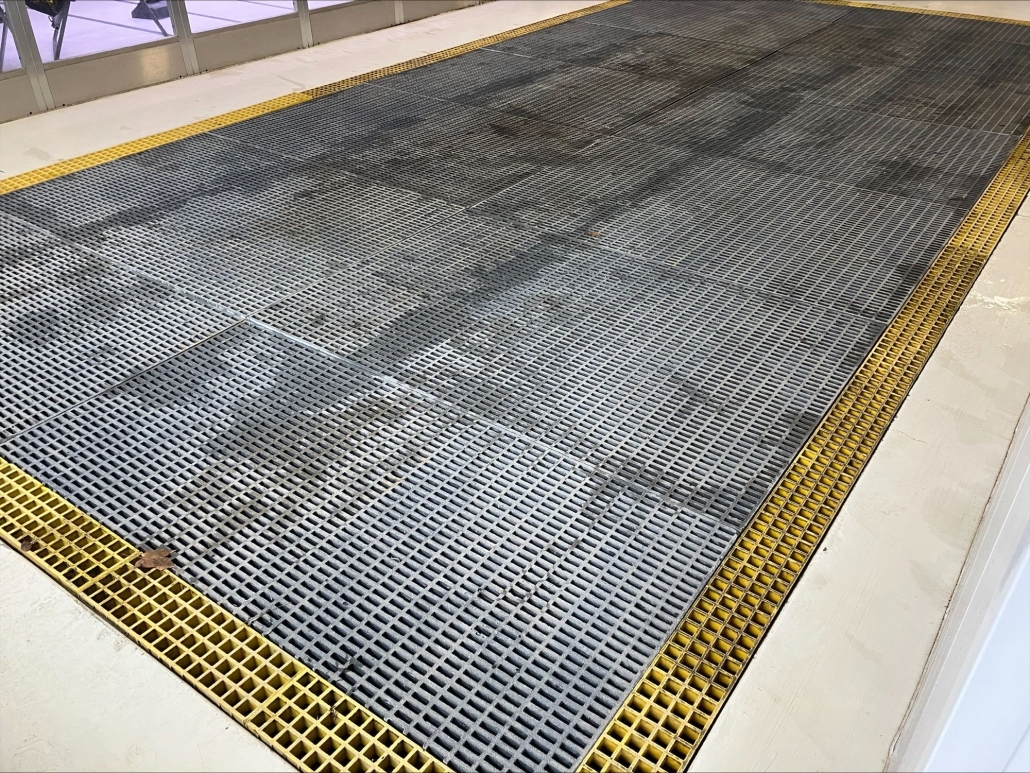

/in alternative to steel grating, Blog, car wash, Fiberglass Grating, Floor Grating, FRP Grating /by Braden TaylorFiberglass FRP Grating is the perfect solution for Car Wash and Vehicle Maintenance facilities like mechanics and oil changers.

National Grating is a leading supplier of FRP solutions for car wash and vehicle maintenance facilities across North America.

FRP Grating uses in Car Wash facilities

Fiberglass FRP Solutions are used in Car Wash facilities primarily as grating for water drainage and in Mechanics for Oils, coolant, and other liquid drainage. The molded or pultruded FRP grating is often used to span a drainage ditch to allow liquids to flow into a drainage system while providing a strong and safe surface for vehicles and customers. For heavy loads High Load Capacity (HLC) or Heavy-Duty FRP Grating is used that can support vehicle weights.

Other FRP applications in vehicle maintenance facilities include grating for walkways, FRP Stair Treads for nonslip stairs, FRP plate for a solid nonslip surface on platforms or walking surfaces and FRP Railing for noncorrosive hand railings.

- Wash Bays

- Troughs

- Drainage Systems

- Trenches

- Walkways

- Grating

- Platforms

- Nonslip stairs

- Railing

National Grating FRP Solutions for Car Washes:

- Molded & Pultruded Grating

- Drainage trenches, flooring, platforms, walkways.

- FRP grating is utilized in car washes for its drainage capabilities, safety features, aesthetic appeal, ease of maintenance, and chemical resistance, making it a versatile and practical solution for flooring and drainage needs in these facilities.

- Heavy Duty Grating

- Engineered to carry heavy traffic like cars, trucks & forklifts.

- Heavy Duty HLC (High Load Capacity) FRP grating is used in car washes due to its strength, durability, corrosion resistance, low maintenance requirements, safety features, and ease of installation, making it an ideal choice for areas with heavy vehicle traffic like those found in car wash facilities.

- FRP Stair Treads and Covers

- Slip-resistant & durable stair solutions.

- FRP stair treads are utilized in car washes for their non-slip properties, corrosion resistance, durability, and ease of maintenance, making them a practical and safe choice for stairs within these facilities.

- FRP Plate

- Resistant to soap, chemicals & water.

- FRP plates are utilized in car washes due to their corrosion resistance, durability, ease of maintenance, and safety features, making them a suitable choice for various applications within these facilities.

Why FRP Grating is perfect for Car Washes:

Durability: FRP grating is commonly used in car wash drains due to its corrosion resistance, durability, and ability to handle heavy traffic and exposure to water and chemicals without deteriorating or requiring frequent replacements.

Corrosion Resistance: FRP materials are resistant to corrosion from water and cleaning chemicals commonly used in car wash operations, ensuring longevity even in harsh environments.

Chemical Resistant: FRP grating is resistant to chemicals commonly used in car wash operations, making it a suitable choice for areas exposed to cleaning agents and detergents without deteriorating or losing its structural integrity.

Non-slip: The non-slip properties of FRP grating make it a safe flooring option for car wash facilities, providing traction even when wet and reducing the risk of slips and falls for both customers and staff.

Strength and Durability: HLC grating is engineered to withstand heavy vehicle traffic, including forklifts and large trucks, making it ideal for areas with high loads like car wash facilities. It is extremely durable and can handle corrosive environments without rusting, ensuring a long-lasting solution.

Safety and Performance: The high strength-to-weight ratio of HLC grating makes it easy to handle and install, providing a safe and stable flooring solution for car wash areas with heavy traffic. Its non-conductive properties also enhance safety in these environments.

Easy Maintenance: FRP Grating is easy to clean and maintain, requiring minimal effort to keep it looking new and ensuring a hygienic environment.

FRP grating is utilized in car washes for its drainage capabilities, safety features, aesthetic appeal, ease of maintenance, and chemical resistance, making it a versatile and practical solution for flooring and drainage needs in these facilities.

National Grating Fiberglass Reinforced Plastic (FRP) Grating Solutions:

- Molded FRP Grating

- Pultruded FRP Grating

- Heavy Duty / High Load Capacity FRP Grating

- Structural Shapes

- Stair Treads and Covers

- Fiberglass Plate

- Fiberglass Tubing

- Fiberglass Railing

- Threaded Rod and Nuts

- Grating Clips

- Specialty Products

National Grating Customer Service

National Grating prides itself on providing exceptional customer service to all customers, big and small.

Reach out to us today for your next FRP Project!

Sales@NationalGrating.com / 1-844-599-0260

Fiberglass FRP Stair Tread Covers Revitalize Old Stairs

/in Alberta, alternative to steel grating, B.C., Blog, Fiberglass Grating, Fiberglass Railing, Fiberglass Walkway, Floor Grating, FRP Grating, FRP Plate, HLC Grating, Ontario, Pultruded Grating /by Braden Taylor

Fiberglass FRP Stair Tread Covers easily install over existing metal, wood or concrete stairs to instantly improve safety, usability, visibility, and aesthetics.

National Grating recently assisted a small business in Ontario to revitalize their old steps with Fiberglass FRP Stair Tread Covers. The outdoor staircase provides access to the Yoga Studio on the second level of the building. The old stairs were rusting and becoming unsightly and hazardous. Fiberglass FRP Stair Tread Covers were easily installed over the existing metal stairs.

Entrances are the first impression for customers approaching your business. The unsightly stairs leading to the Yoga Studio not only provide access to clients, but they are also the first thing people see before they enter the business and the last thing they see when they leave. The rusting, old stairs looked terrible and presented a bad first impression for clients. The Yoga Studio decided it was time for an update! New National Grating FRP Stair Treads cover up old stairs without need for a new rebuild, while providing added safety through bright yellow nosing and a grippy anti slip coating.

New FRP Stair Treads cover up old unsightly stairs without need for a new rebuild, while providing added safety through bright yellow nosing and a grippy anti slip coating.

People use FRP (fiberglass reinforced plastic) stair tread covers for several reasons, including safety, durability, and ease of installation. FRP stair tread covers are known for their non-slip properties, which enhance safety on stairs. They are lightweight, making them easy to install, and fiberglass-reinforced plastic is durable and resistant to corrosion, making it a suitable material for enhancing stair safety.

Fiberglass FRP Stair tread covers from National Grating have been widely installed over metal, wooden, and concrete stairs with ease.

FRP Stair Tread Cover Benefits

The benefits of using FRP (fiberglass reinforced plastic) stair tread covers over traditional materials include:

- Safety: FRP stair tread covers are known for their non-slip properties, which enhance safety on stairs.

- Durability: Fiberglass-reinforced plastic is durable and resistant to corrosion, making it a suitable material for enhancing industrial stair safety.

- Ease of Installation: FRP stair tread covers are lightweight, making them easy to install.

- Versatility: They can be used on various surfaces such as step ladders, concrete, wood, and metal stairwells.

- Cost-Effectiveness: They can cover worn-out or outdated steps, saving money by avoiding the need for expensive rebuilds.

Overall, the use of FRP stair tread covers offers advantages in terms of safety, durability, ease of installation, versatility, and cost-effectiveness compared to traditional materials.

FRP Stair Tread Cover Applications

FRP (fiberglass reinforced plastic) stair tread covers have various applications due to their beneficial properties. Some of the common applications include:

- Interior and Exterior Use: FRP stair tread covers are suitable for both interior and exterior applications, making them versatile for use in different settings.

- Industrial Settings: They are used in industrial settings to enhance safety on stairs, walkways, and platforms, especially in heavy traffic areas where anti-slip surfaces are essential.

- Outdoor Walkways: FRP stair tread covers are ideal for outdoor walkways due to their anti-slip surfaces, providing an important safety feature in areas with heavy foot traffic.

- Various Substrates: They can be used on a variety of substrates such as concrete, wood, stone, metal, and brick stairs, making them suitable for different types of stairwells.

- Safety Enhancement: These covers are designed to reduce accidents caused by slips and falls, making them a practical and affordable solution for protecting steps.

FRP stair tread covers are widely used in industrial, outdoor, and indoor settings to improve safety, protect steps, and provide anti-slip surfaces on various substrates.

How to Install FRP Stair Tread Covers

To install FRP (fiberglass reinforced plastic) stair tread covers over metal stairs, the following general steps can be followed:

- Contact National Grating to speak with an experienced individual to help you make the best decision.

- Measure: Take measurements of the stair treads so the National Grating fabrication team can size your stair tread covers for a perfect fit. Assess how many stair tread covers you require.

- Preparation: Ensure that the metal stairs are clean, dry, and free from any debris or protrusions that could affect the installation.

- Attachment: Use stainless steel or zinc plated saddle clips and domed or flat head bolts suitable in length for the depth of the FRP tread covers. Pre-drill the FRP to the proper hole size for the screws being used.

- Installation: Pre-position the FRP covers in place to ensure the fit, then install screws about 6 inches from the ends of the piece, and additional screws every 2 feet as needed.

Once installed, ensure that the covers are securely and firmly attached and provide a non-slip surface for safe use before opening to the public.

Other Fiberglass FRP Stair Options from National Grating

Fiberglass FRP Stair Treads

National Grating also has full FRP Molded Stair Treads for situations when the existing stair needs to be replaced or for new staircase construction.

Fiberglass stairs are the best solution for outdoor anti-slip stairs. They outlast traditional building materials and are easy to install. Stair treads made of FRP grating are lightweight, easy to fabricate, and highly durable.

Fiberglass stair treads are available as molded FRP treads with yellow nosings and a gritted top surface for all weather grip, for the ultimate in safety. Non-slip stair treads are corrosion resistant and lightweight.

Fiberglass stairs can be fabricated from fiberglass grating, which opens up the options enormously for color, resin, grit, mesh size, and whether molded fiberglass grating or pultruded FRP grating is more suitable.

Fiberglass FRP Railing

Fiberglass Railing Systems are a natural accompaniment to fiberglass stairs for corrosive environments – all components will outlast and outperform steel, stainless steel, wood, or other traditional materials.

FRP railing is non-conductive and in cold environments does not become cold to the touch like metal.

Fiberglass FRP Plate

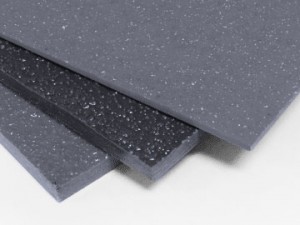

Fiberglass Plate is a large sheet of FRP that comes in a variety of colors with an anti slip, grippy coating. FRP plate is perfect to cover unsightly landings and platforms with a solid anti slip surface.

FRP Plate comes in thicknesses ranging from 1/8″ to 3/4″ and various resin systems. Plate can be installed on fiberglass grating, metal or concrete, for heavy loads and complete flooring system with all the benefits of fiberglass reinforced panels.

National Grating Customer Service

National Grating prides itself on providing exceptional customer service to all customers, big and small.

Reach out to us today for your next FRP Project!

Sales@NationalGrating.com / 1-844-599-0260

National Grating Announces Eastern Facility Expansion in Woodstock, Ontario

/in alternative to steel grating, Barrie, Blog, car wash, Detroit, Dock Repair, Fiberglass Grating, FRP Grating, Guelph, Hamilton, Kanata, Kingston, Kitchener, London, marina walkways, Milton, News, Niagara Falls, Ontario, Oshawa, St. Catharines, Toronto, Windsor /by Braden Taylor

National Grating (www.NationalGrating.com) a leading North American provider of FRP Grating and FRP (Fiberglass Reinforced Plastic) Composite Structural solutions, is proud to announce an eastern facility expansion to a new location in Woodstock, Ontario, Canada. This strategic expansion is in response to the growing demand for FRP products and the company’s commitment to providing exceptional service to its customers.

“We have expanded our Ontario operations by moving to a new two-acre facility just 10 mins from Highway 401 with 5,000+ pieces of Fiberglass FRP Grating, Shapes, Beams and Structure in stock.” Dylan Powell, Sales Manager. “This Eastern Distribution facility will help us to service our customers up and down Eastern North America. We work hard to commoditize FRP and make it accessible and available to the consumer!”

“We will maintain our Western branches in Vancouver and Kelowna in British Columbia and Spruce Grove in Alberta in addition to our dozen stocking locations across the USA. We have always prided ourselves in having the best customer service in the industry and this expansion is to ensure that continues.” Rick Van Rikxoort, National Grating President.

The new facility boasts a large inventory of FRP products, including bulk FRP molded and pultruded grating, as well as a wide range of specialty items such as FRP Stair Tread, Fiberglass Plate, Fiberglass Railing, Fiberglass Tubing, Fiberglass Beams, Fiberglass C-Channel, Fiberglass I-Beams, Fiberglass H-Beams and FRP Threaded Rod and Nuts. With this extensive inventory, National Grating is well-positioned to serve the needs of metal fabricators, contractors, and construction companies in Ontario and beyond. The company’s ability to ship quickly for projects, coupled with its custom fabrication services, makes it a valuable partner for businesses seeking durable and versatile FRP solutions.

“Feel free to drop by our newest location to view thousands of FRP Grates and Shapes in stock!” Dylan Powell, Sales Director “Pickup a sample when you go! We have tons of inventory to look at and tons of samples to take back to your office to show your staff the quality that goes into our products.

The Ontario facility will offer a complete line of FRP solutions for various applications, including walkways and platform grating, railings, and stair treads with a non-slip AODA, ADA compliant finish. In addition, National Grating’s FRP products are known for their corrosion resistance, significant weight savings, and ease of installation, making them an ideal alternative to traditional materials.

National Grating’s new Eastern Distribution Center represents a significant step forward in furthering the company’s commitment to service and quality and strengthening the company’s ability to serve its valued customers across North America. With its extensive inventory and superior logistics network, the company is well-equipped to provide fast delivery of fiberglass grating all major cities in Eastern Canada and the USA.

“National Grating has experienced huge growth over the past several years. We saw a need for an Eastern distribution hub to better serve our customers in the area. The massive amount of metal fabricators and contractors that have been switching over to our FRP Grating products has really been the impetus for his new location and we look forward to providing them with exceptional service.” Dylan Powell, National Grating Sales Director.

“We pride ourselves on providing the absolute best customer service in the industry with dedicated sales support, fast shipping and a great product. Give us a call and talk to a real person about your projects FRP needs.” Rick van Rikxoort, National Grating President.

National Grating Ontario FRP Solutions and Services

- Bulk Inventory

- National Grating specializes in having high levels of inventory on hand. This allows customers to view the product at our facility while also allowing us to quickly send samples and products to your office, factory or construction site.

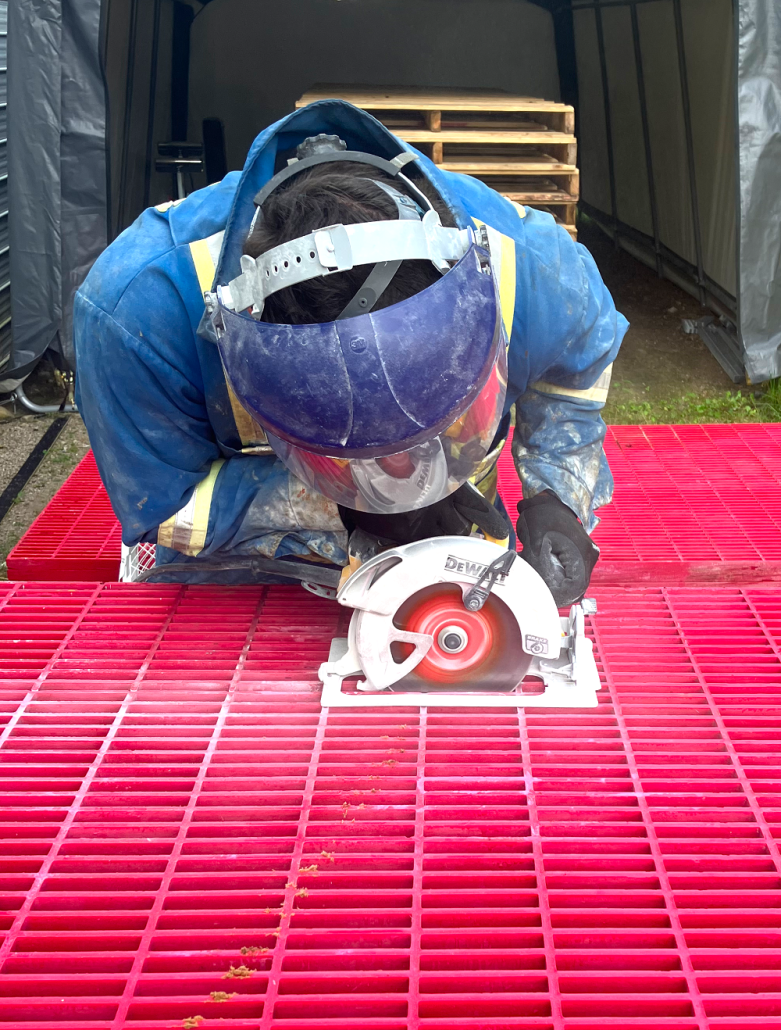

- Custom Fabrication Services

- Our FRP experts are highly experienced in providing custom solutions to a variety of applications. Whether requirements call for grating cut to specific lengths, widths or sizes, our fabrication department has the experience to accommodate a variety of requests. Custom services are offered by the new National Grating Ontario location with an in-house fabrication shop and experienced professionals who work closely with clients to turn their design concepts into high-quality finished products.

- National Grating fabrication services involve the use of advanced fabrication techniques and technical expertise to produce custom FRP structures, grating, platforms, handrails, beams, and other products. Custom FRP fabrication services provide corrosion-resistant, durable, and customized solutions that meet specific design and functional requirements.

- On-site Training and Education

- We are FRP experts with years of experience that we want to share. If you are interested in booking one of our local FRP experts to educate you and your team on FRP applications, uses and advantages please contact us at:

1-844-599-0260 or sales@nationalgrating.com

- We are FRP experts with years of experience that we want to share. If you are interested in booking one of our local FRP experts to educate you and your team on FRP applications, uses and advantages please contact us at:

National Grating Fiberglass Reinforced Plastic (FRP) Grating Solutions in Ontario:

- Molded FRP Grating

- Pultruded FRP Grating

- Heavy Duty / High Load Capacity FRP Grating

- Structural Shapes

- Stair Treads and Covers

- Fiberglass Plate

- Fiberglass Tubing

- Fiberglass Railing

- Threaded Rod and Nuts

- Grating Clips

- Specialty Products

National Grating Ontario Location:

684470 Road 68

Beachville, ON, Canada

N0J 1A0

Just outside Woodstock across from the Oxford Drive In – minutes from the 401 – 1.5 Hours from Toronto and ~ 2 hours from Detroit or Buffalo crossings.

About National Grating – FRP Solutions

National Grating is a North American provider of FRP Grating and Structural solutions. The company offers a wide range of FRP products and fast delivery via its superior logistics network. With a focus on quality, durability, and customer satisfaction, National Grating is a trusted partner for businesses across North America. For more information about National Grating and its FRP products, visit nationalgrating.com.

Pultruded FRP Grating: The Ideal Solution for Canadian Marine Dry Docks and Rail Yards

/in Alberta, alternative to steel grating, B.C., Blog, Dock Repair, Fiberglass Grating, Fiberglass Railing, Fiberglass Walkway, marina walkways, Ontario, Pultruded Grating /by Braden TaylorNational Grating has been seeing high levels of interest in Pultruded FRP Grating for applications such as Marine Dry Docks across Canada, North America and even as far north as Alaska due to its winter advantages.

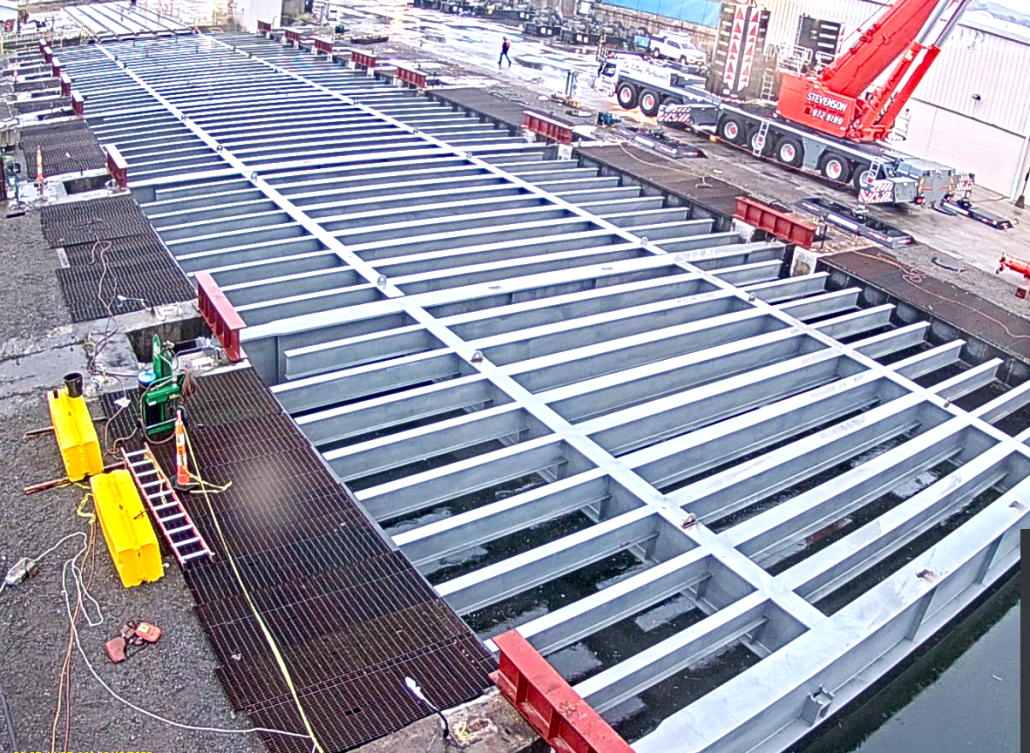

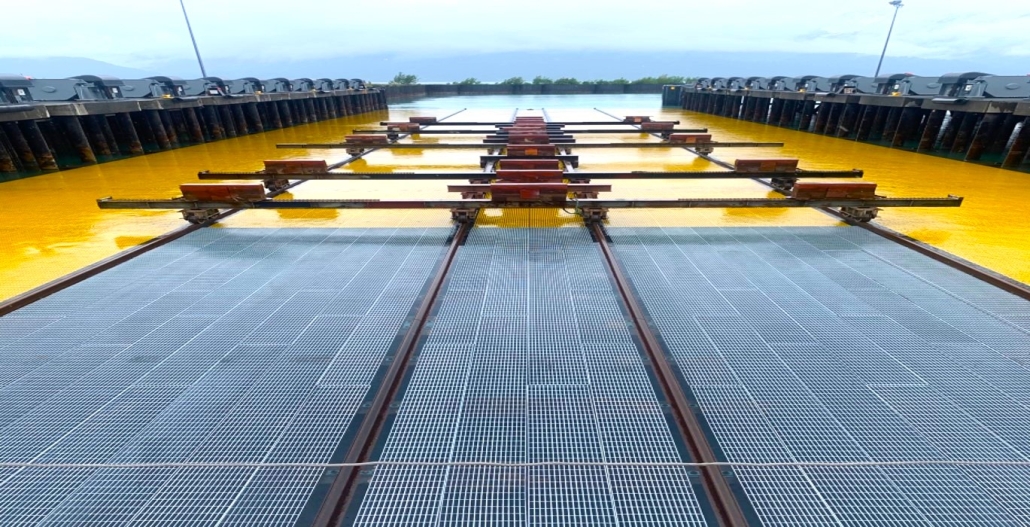

This Marine Towing Drydock operating in the Great Lakes has found the perfect solution for its demanding environment with the implementation of Pultruded T-5000 FRP Grating from National Grating. This innovative grating, engineered from fiberglass-reinforced plastic (FRP), offers a comprehensive set of advantages that address the specific needs of the rail yard, ensuring enhanced performance and durability.

Corrosion Resistance and Longevity

Pultruded FRP Grating is designed to withstand the harshest environments, making it an ideal choice for the Marine Towing Drydock Rail Yard. Its superior corrosion resistance, surpassing traditional materials such as stainless steel, aluminum, and galvanized gratings, ensures longevity and minimizes maintenance requirements.

Heavy-Duty Performance

Engineered to carry higher loads, Pultruded T-5000 Grating delivers exceptional strength and stiffness, making it well-suited for the rigorous demands of the rail yard. Its heavy-duty design provides the necessary support for various operational activities, contributing to a reliable and robust infrastructure.

Safety and Efficiency

The safety surface of Pultruded T-5000 Grating, featuring a coarse epoxy grit, enhances worker safety, even in challenging conditions. This prioritization of safety aligns with the dry docks commitment to maintaining a secure working environment for its personnel.

Low Maintenance and Cost-Effectiveness

The implementation of Pultruded T-5000 Grating offers the Marine Towing Drydock Rail Yard a low-maintenance solution, reducing the need for frequent repairs and upkeep. Furthermore, its cost-effectiveness and long-term performance make it a valuable investment for the rail yard’s operational infrastructure.

Pultruded Grating stands as the optimal choice for a Marine Drydock, providing a durable, high-performance solution that addresses the specific requirements of the environment. Its corrosion resistance, heavy-duty performance, safety features, and cost-effectiveness make it an indispensable asset for the rail yard’s ongoing success and operational efficiency.

Pultruded FRP Grating in other Industries:

Pultruded FRP grating is commonly used in various industries due to its superior strength, corrosion resistance, cold weather advantages and durability. Some potential industries where Pultruded T-5000 grating may be successfully implemented include:

- Marine and Offshore: Due to its corrosion resistance and durability, Pultruded FRP grating is suitable for marine and offshore applications, such as shipyards, docks, and offshore platforms.

- Industrial Manufacturing: Industries requiring heavy-duty flooring and grating solutions, such as manufacturing plants, chemical processing facilities, and industrial warehouses, can benefit from the high-strength and low-maintenance characteristics of Pultruded FRP grating.

- Transportation: The transportation sector, including railway facilities and infrastructure, can utilize Pultruded FRP grating for its durability and resistance to environmental factors.

- Construction and Infrastructure: In construction and infrastructure projects, Pultruded FRP grating can be used for walkways, platforms, and structural applications due to its high strength and corrosion resistance.

Characteristics of Pultruded FRP grating make it a versatile solution for a wide range of industries that require durable, corrosion-resistant, and high-strength grating products.

Why choose Pultruded FRP Grating?

Pultruded FRP (Fiber Reinforced Plastic) grating is often chosen over molded FRP grating or steel grating for industrial applications due to several key differences in their characteristics and performance. Here are the main reasons for choosing pultruded FRP grating:

Strength and Stiffness: Pultruded grating has a higher fiberglass concentration, making it stronger and stiffer than molded grating. This characteristic makes it suitable for applications requiring higher load-bearing capacity and longer spans.

Corrosion Resistance: Pultruded grating offers excellent corrosion resistance, making it ideal for harsh industrial environments where exposure to chemicals, moisture, and corrosive elements is a concern.

Heavy-Duty Applications: Due to its superior strength and load-bearing capabilities, pultruded grating is well-suited for heavy-duty industrial applications, such as manufacturing plants, chemical processing facilities, and offshore platforms.

Customization and Versatility: Pultruded grating can be customized to meet specific project requirements, offering versatility in panel sizes, resin systems, and other design features to accommodate various industrial applications.

Fire Retardant Properties: Some pultruded grating products are manufactured with fire retardant properties, making them suitable for applications where fire safety is a concern.

Pultruded FRP grating is preferred over molded grating for industrial applications due to its higher strength, stiffness, corrosion resistance, suitability for heavy-duty use, and the ability to be customized to meet specific project requirements.

Pultruded FRP VS Steel and Wood Grating

Pultruded FRP (Fiber Reinforced Plastic) grating is often chosen over steel grating for industrial applications due to several key advantages. Here are the main reasons for choosing pultruded FRP grating over steel grating:

- Corrosion Resistance: Pultruded FRP grating offers superior corrosion resistance compared to steel grating, making it ideal for corrosive environments, including chemical processing, marine, and industrial settings.

- Strength-to-Weight Ratio: Pultruded FRP grating provides high strength with a lower weight compared to steel, offering easier installation and reduced structural support requirements.

- Low Maintenance: FRP grating requires minimal maintenance and is resistant to chemicals, making it an attractive choice for industrial applications where exposure to water, chemicals, and cleaning agents is common.

- Safety Surface: The walking surface of pultruded grating often has a coarse epoxy grit bonded to the bearing bars, providing a safe surface for workers, even in wet conditions.

- Customization and Versatility: Pultruded FRP grating can be customized to meet specific project requirements, offering versatility in panel sizes, resin systems, and other design features to accommodate various industrial application.

Pultruded FRP grating is preferred over steel and wood grating for industrial applications due to its superior corrosion resistance, high strength-to-weight ratio, low maintenance requirements, safety features, and customization options. These advantages make it a versatile and cost-effective solution for a wide range of industrial settings.

Other Industries Utilizing Pultruded FRP Grating:

- chemical processing

- food & beverage

- marine

- aquatic centers

- oil & gas

- power

- manufacturing

- construction

- pharmaceutical

- metals & mining

- pulp & paper

- recreation

- water parks

- telecommunications

- shipping centers

- transportation facilities

- water & waste treatment

FRP Grating Winter Applications

/in alternative to steel grating, Blog, Fiberglass Grating, Fiberglass Walkway, Floor Grating, FRP Grating, FRP Plate, Molded-Fiberglass-Grating, News, non-skid, non-slip /by Braden TaylorWinter Applications for FRP Grating, Stair Treads and Railings

As the fall and winter seasons approach, many are gearing up to face the challenges that come with cold, wet, icy and slippery conditions. FRP Grating and Structural products are ideal for cold weather and arctic installations as they have very low thermal conductivity and do not become brittle in the extreme cold faced by many across North America.

One of the most significant advantages of FRP grating, stair treads and stair tread covers in winter is their exceptional slip resistance. FRP surfaces are engineered to provide reliable traction, even when wet or covered in snow and ice. This can prevent accidents and ensure safe movement on stairs and walkways, both indoors and outdoors.

Slips trips and falls are the #1 cause of workplace injuries.

Choose FRP Grating for a safe workspace!

Consider FRP Grating, Stair Treads, and Railings for the following Benefits/Advantages:

1. Safety in Slippery Conditions:

One of the most significant advantages of FRP grating, stair treads, and handrails in winter is their exceptional slip resistance. FRP surfaces are engineered to provide reliable traction, even when wet or covered in snow and ice. This can prevent accidents and ensure safe movement on stairs and walkways, both indoors and outdoors.

2. Corrosion Resistance:

Winter weather often means exposure to salt and de-icing chemicals, which can be corrosive to traditional materials like steel. FRP is highly resistant to corrosion, making it an ideal choice for outdoor installations, such as walkways and handrails. Its durability ensures that these elements remain safe and functional throughout the winter season.

3. Low Thermal Conductivity:

FRP has a low thermal conductivity, which means it does not readily transfer heat or cold. In winter, this can be a significant advantage. Handrails made of FRP won’t become uncomfortably cold to the touch, providing a more pleasant experience for those who need to hold onto them in chilly weather.

4. Low Maintenance:

FRP products require minimal maintenance. They do not rust, warp, or rot, and they’re highly resistant to the effects of freezing and thawing. This translates to cost savings and less time spent on upkeep during the winter season.

5. Longevity and Durability:

FRP materials are built to last. They can withstand the harsh conditions of winter without deteriorating. This long-term durability ensures that your infrastructure investments remain sound and reliable year after year.

6. Easy Installation:

FRP products are lightweight and easy to install, which can save time and resources, especially during winter when weather-related challenges can increase project complexities.

Embracing FRP grating, stair treads, and handrails during the winter season is a smart choice for safety, reliability, and longevity. These versatile materials offer a range of benefits that can help ensure that your infrastructure remains secure and functional, regardless of the weather conditions. Whether it’s in industrial settings, commercial properties, or residential areas, the advantages of FRP are undeniable during the challenging winter months.

National Grating FRP Products Designed for Winter Applications

Fiberglass Stair Tread Covers

Fiberglass stair tread covers are excellent for use in heavy traffic areas, such as outdoor walkways. The anti-slip surfaces of these FRP stair tread covers are an important safety feature in walkways where moisture is present.

FRP Stair Tread Covers are molded, non-slip and gritted, with a yellow nosing for the ultimate in non-slip, high visibility surface. They are the ideal solution for outdoor and slippery all-weather applications, featuring high corrosion resistance, durable grit, and easy installation.

FRP Stair tread covers can be installed over wood, concrete or metal steps and are manufactured with a quartz grit-top surface and a standard nosing of highly visible yellow.

Fiberglass Stair Treads

Fiberglass stairs are the best solution for outdoor anti-slip stairs. Stair treads made of FRP grating are lightweight, easy to fabricate, and highly durable.

Fiberglass stair treads are available as molded FRP treads with yellow nosing’s and a gritted surface, for the ultimate safety in wet or icy slippery conditions.

Optional gritted anti-slip top surface promotes safety while the large open area of the grating allows for water, snow and ice to simply pass through the material.

Fiberglass Plate

Fiberglass plate is light in weight and is easy to install, and at the same time is durable and sturdy. Pultruded Fiberglass Plate is industrial anti-slip flooring that is corrosion resistant and outlasts traditional building materials like steel and even stainless-steel plate. Most safety flooring applications will benefit from using Fiberglass Plate, and the different types of grit (smooth, fine, diamond) can give slip resistance in a wide variety of slippery situations.

Molded FRP Grating

The ultimate safe walking surface for walkways, docks with an optional gritted anti-slip top surface that promotes safety while the large open area of the grating allows for water, snow and ice to simply pass through the material.

Heavy Duty Fiberglass Grating

Heavy Duty Grating is used to covers areas with heavy traffic.

Our High Load Capacity (HLC) molded grating is heavy duty, corrosion-resistant and low-maintenance. It’s engineered to carry heavy traffic like trucks and forklifts. HLC grating has many advantages over steel grating for performance and cost effectiveness. With a much higher strength-to-weight ratio, molded HLC fiberglass grating has optional top grit to provide extra grip in slippery outdoor applications.

Fiberglass Railing

Fiberglass Railing, Handrail and Ladder Systems are a long-lasting, low-maintenance solution for harsh outdoor environments. FRP railing systems provide inherent corrosion resistance, low thermal conductivity and they are easy to fabricate and install. The installed cost is much lower than steel, and because of the long life and low maintenance life cycle, the costs of fiberglass railing are significantly lower than traditional materials over their lifetime.

Fiberglass FRP Docks

/in alternative to steel grating, Blog, Fiberglass Grating, Fiberglass Walkway, marina walkways /by NG AdminChoose FRP Grating for your Next Dock Project!

When it comes to constructing a dock, traditional materials such as wood have long been the norm.

As FRP grating is extremely durable and can withstand extreme weather conditions, it is fast becoming the preferred alternative to wooden docks.

Strength

Fiberglass grating is incredibly strong and corrosion resistant, making it a great option for docks, decks, and marina ramps and wharves. It can withstand extreme temperatures, high winds, and heavy rain, without showing signs of wear and tear. Wood is vulnerable to rotting, warping, and cracking, which can result in costly repairs and replacements.

Safety

Fiberglass grating is slip-resistant, which makes it a safer choice for a dock than wood. Wet wood can be extremely slippery, increasing the risk of slips and falls, especially for children and the elderly. FRP grating has a non-slip surface that provides traction even when it is wet, making it a safer option for a dock.

Low Maintenance

One of the biggest advantages of using fiberglass grating for a dock is the low maintenance requirements. Unlike wood, FRP grating does not require sealing, staining, or painting. It is also resistant to mildew and rot, so it does not need to be treated with chemicals to prevent decay. This means that it will last longer and require less upkeep than wood.

We offer 4 primary profiles for FRP docks:

MOLDED GRATING: 1.5” Square mesh pattern and ¾” Mini-mesh.

PULTRUDED GRATING: T-1800 and I-4000

ADA Compliant options:

ADA guidelines state the maximum allowable space between bearing bars is a 1/2”.

Our Mini-mesh grating and Pultruded options are all ADA compliant.

Fiberglass Grating is a far superior alternative to wood for building a dock. It is durable, slip-resistant, low-maintenance, and versatile.

Call us at 1.844.599.0260 when planning your new dock or re-furbishing an existing one.

With 3 warehouse locations in Ontario and BC, we can ship anywhere in Canada including Toronto, Montreal, Vancouver, Calgary, Edmonton, Gatineau, Ottawa, Winnipeg, Quebec City, Hamilton, Kitchener, London, Victoria, Halifax, Oshawa, Windsor, Saskatoon, St. Catharines, Niagara Falls, Regina, St. John’s, Kelowna, Barrie, Sherbrooke, Guelph, Kanata, Abbotsford, Trois-Rivières, Kingston, Milton, Moncton, White Rock, Nanaimo, Brantford, Chicoutimi – Jonquière, Saint-Jérôme, Red Deer, Thunder Bay, Lethbridge, Kamloops, Sudbury, Saint-Jean-sur-Richelieu, Peterborough, Chilliwack, Châteauguay, Belleville, Sarnia, Airdrie, Drummondville, Welland – Pelham, Fort McMurray, Prince George, Sault Ste. Marie, Fredericton, Saint John, Medicine Hat, Grande Prairie, Granby, Bowmanville – Newcastle, Beloeil, Charlottetown, Vernon, North Bay, Saint-Hyacinthe, Brandon, Joliette, Courtenay, Cornwall, Victoriaville, Woodstock, St. Thomas, Chatham, Georgetown, Salaberry-de-Valleyfield, Spruce Grove, Shawinigan, Rimouski, Bradford, Campbell River, Penticton, Prince Albert, Stouffville, Sorel, Mission, Leamington, Orangeville, Leduc, Orillia, Stratford, Moose Jaw, Cochrane, Lloydminster, and many more!

National Grating: #102 – 5041 Regent St. Burnaby, BC V5C 4H4 Canada

Alternatives to Steel Grating – New or Replacement

/in alternative to steel grating, Blog, Fiberglass Grating, FRP Grating, FRP Supplier /by alph@b3tResources

Popular Pages

FRP Specs & Topics

- National Grating announces new FRP location in Edmonton, Alberta!

- National Grating Offers Custom Cutting and Fabrication of FRP Solutions

- National Grating announces opening of new facility in Ontario with Grand Opening BBQ

- FRP Solutions for Rooftop Walkways

- National Grating FRP Solutions Increase Safety

Customer Support

or call us toll free:

1-844.599.0260

#102 - 5041 Regent St.Burnaby, BC V5C 4H4 Canada